High-Density Insert Roller

Series 1000Ensure safe accumulation of small or fragile products with the Intralox Series 1000 High-Density Insert Roller belt.

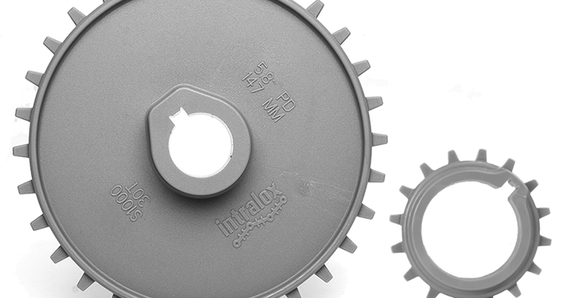

Used across many industries—especially beverage—S1000 High-Density Insert Roller belting offers low back pressure accumulation to prevent product damage from packaging to palletizing. It features a 0.60-in (15.2-mm) pitch that provides exceptional tight transfer capability and eliminates the need for dead plates.

- Groups of four rollers in 3-in (76.2-mm) increments improve product control and stability

- Lower coefficient of friction reduces line pressure

- Minimal catchpoints promote worker safety

- 0.75-in (19.1-mm) nose-roller transfers

| in | mm | |

| Pitch | 0.60 | 15.2 |

| Minimum Width | 9 | 229 |

| Width Increments | 3.00 | 76.2 |

| Open Area | 4% | |

| Hinge Style | Closed | |

| Rod Retention; Rod Type | Barn door; unheaded | |

- Contact Intralox for precise belt measurements and stock status before designing equipment or ordering a belt.

- Fully flush edges on one side and closed edges on opposite side.

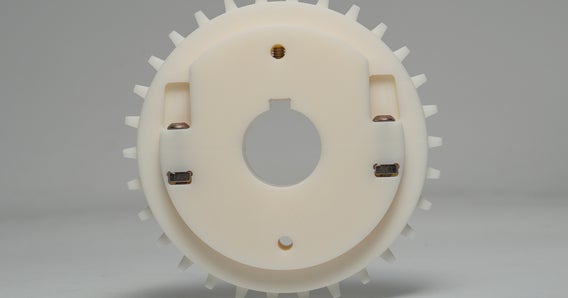

- Rollers protrude above and below the belt surfaces.

- Uses one unheaded rod across the entire belt width on each belt row.

- Each belt material has a default rod material. Other rod materials are available. Intralox can help identify the best belt and rod material combination for your application.

- Detailed material information is provided in Product Line.

- Minimal back tension required for sprocket engagement

- For activated roller applications, place wearstrip directly under rollers.

- For low back-pressure applications, place wearstrip between rollers in parallel. Wearstrip of 0.50 in (13 mm) wide is recommended to allow some manufacturing and installation tolerance in the conveyor, while providing adequate support to the belt. Maximum allowed wearstrip width is 0.75 in (19 mm).

- Compatible with 0.75 in (19.1 mm) diameter nosebars for tight transfers. For high-speed and load applications, a nose-roller is recommended.

- Yellow acetal rollers are 0.30 in (7.6 mm) wide and 0.48 in (12.1 mm) diameter. Rollers are on the belt rod.

- Roller density: 320 rollers/ft2 (3440 rollers/m2).

- Roller indent: 0.70 in (17.8 mm) from edge of belt to edge of roller.

- Sprocket indent: 1.5 in (38.1 mm) from edge of belt.

- Sprocket spacing: 3.0 in (76.2 mm) apart.

| Belt Material | Default Rod Material, Diameter 0.18 in (4.6 mm) | Belt Strength | Temperature Range (continuous) | Belt Mass | |||

|---|---|---|---|---|---|---|---|

| lbf/ft | N/m | °F | °C | lb/ft² | kg/m² | ||

| Acetal | Nylon | 1,000 | 14,600 | -50 to 200 | -46 to 93 | 1.87 | 9.13 |