Welcome to the Future

Your one source for risk-free, future-ready, proven Packer to Palletizer conveyance belting solutions.

Ready for Anything

Intralox’s Packer to Palletizer Conveyance Belting Portfolio

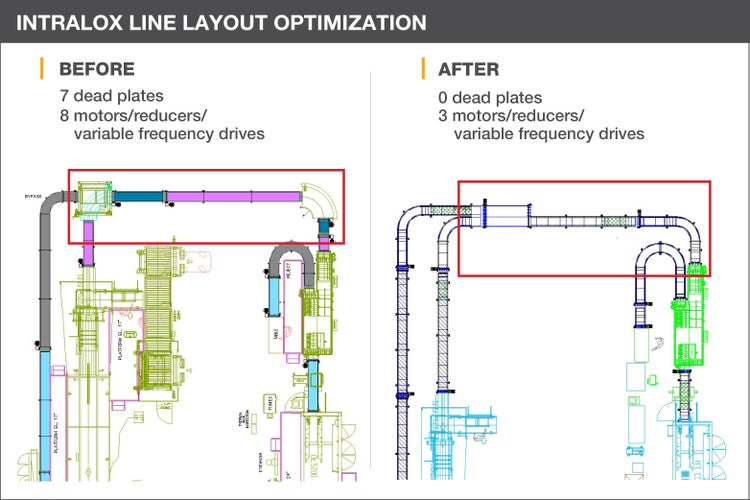

- Experience gentle, fast product handling by eliminating dead plates

- Flexibility to handle all package types on the same line

- Fast, low-cost installation

- Operational efficiency in small footprints

- Tight transfers that eliminate your dead plates

By working with Intralox early in your project, you can achieve this and more with the right components and the right services before, during, and after installation—delivered on time, every time.

Since the Intralox install, we have had no downtime resulting from the curve. This is a great example of problem solving, improving line efficiency and throughput, and reducing operational costs.

Plant Operations Manager

Global Beverage Bottler

* Data varies based on application and customer environment

The Benefits of Intralox’s Packer to Palletizer Belting Portfolio

Driven by Technology:

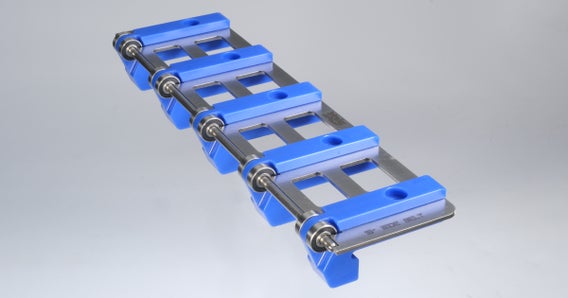

Only three belt series for complete conveyor system

- Requires less spares stock

- Easier and faster to get the right belt

- Reduces chance for errors

- Easier to train staff

One 0.75-in nose-roller for straight-run, accumulation, and radius belts

- One part for all conveyors

- Standard replacement part

- Eliminate dead plates

Same-day shipping for the most common belts in standard widths (most markets)

- Requires even less spares stock

- Same-day service always, with no extra fees

- Fixed part number promotes ease of doing business

One belting source, numerous advantages

- Reduced risk for errors

- Built-in compatibility with Intralox equipment