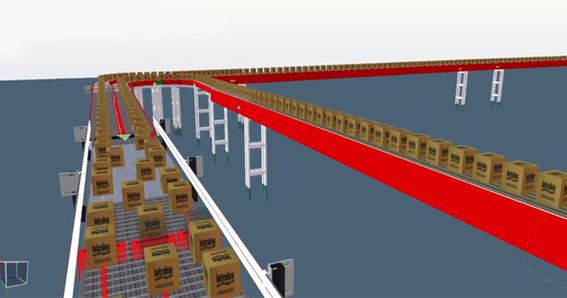

Simplified Layouts. Reduced Costs. Future-ready Flexibility.

Intralox line layout optimization consulting helps you unlock potential and improve overall performance. With industry expertise and transformative technologies, we help you achieve future-ready flexibility and other results not possible with traditional technologies.

By working with Intralox in the early stages of your project, you can:

- Increase functionality

- Reduce costs, including installation costs and total cost of ownership

- Reduce or eliminate downtime

- Improve overall performance—in a single application or on an entire line

- Decrease both the amount of floor space and number of conveyors you need

Why Layout Optimization?

Optimized layouts are less complex and run faster, increasing accumulation and throughput while decreasing the number of operators needed. Intralox’s transformative technologies ensure you stay future ready, empowering you to reliably handle the widest range of products or package types.