- Intralox FoodSafe

Protect Your Line. Protect Your Profits. Protect Your Brand.

Become Intralox FoodSafe

Created to optimize your direct food–contact conveyors, The Intralox® FoodSafe™ System is an unrivaled, in-depth approach to meeting your plant’s daily production goals sustainably.

Our comprehensive system of Products, Services, and Training is designed to help you achieve the best possible outcomes in uptime, throughput, and food safety.

Intralox FoodSafe Product Portfolio

Belts, tools, and components reimagined for modern food processing

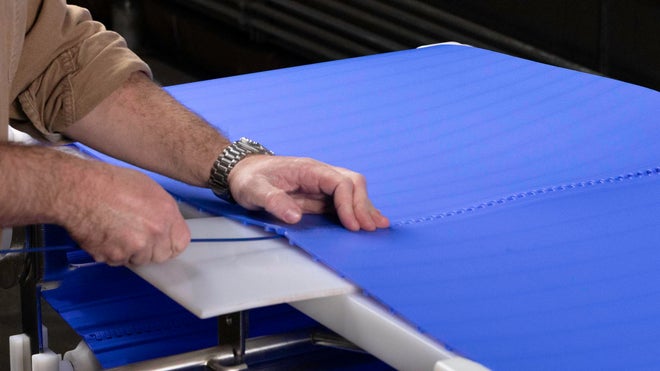

Modular Plastic BeltingSimpler, stronger, and safer

Designed to maximize operational performance and food safety, Intralox FoodSafe modular plastic belting (MPB) empowers you to boost uptime and throughput while mitigating foreign material risks.

Available in a range of materials and designs, Intralox FoodSafe MPB includes robust, fault-tolerant options that minimize belt breakage. When paired with our industry-leading expertise and services, Intralox MPB can set your facility on a course of long-term success.

Benefits

- Prevent breakage caused by belt mishandling

- Maximize belt life in high-impact or abrasive applications

- Increase safeguards with detectable materials

- Maintain belt strength and durability in high-chemical-exposure applications

Producing Results

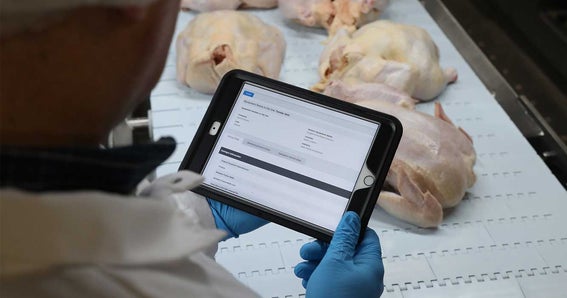

Services

Food safety and application experts identify and mitigate risks on your lines

- FoodSafe Conveyor Program (Assessments and Workshops)

- Field belt splicing and system health checks

- Conveyor design

Training

Digital tools and hands-on instruction to elevate your teams’ conveyor expertise

- Professional workshops, training sessions, and certification pathways from Commercial Food Sanitation, an Intralox company

- Intralox Learn, an on-demand digital training program (available to select partners)

- Maintenance training

- Performance Support Videos