Snack industry belting solutions

Leading snack food producers worldwide trust Intralox to keep their production lines running.

Our conveyor belt and equipment solutions for handling chips, salty snacks, nuts, seeds, and more help you eliminate downtime, reduce total cost of ownership, and achieve problem-free conveyance. Our industry experts partner with you to ensure you receive the correct solutions and service, when you need them.

How we ensure seamless customer experiences:

- Robust supply chain infrastructure backed by dedicated global resources

- Global account structures and positioning

- Unmatched expertise to optimize your plant, application, and equipment

Snack plant processing areas

Where can Intralox make the difference for you?

ReceivingTake abrasion resistance to a new level

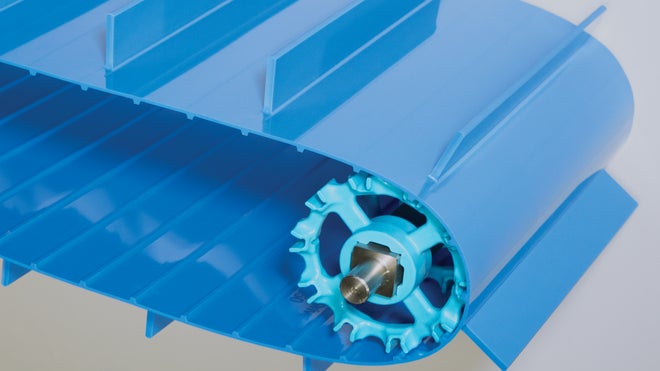

In the harsh, highly abrasive conditions of the receiving area, debris and grit can migrate and accumulate between belt modules and rods, causing wear and shortened belt life. Series 1700 and 1750 Flush Grid belts are designed specifically to address high-abrasion challenges that can lead to shortened belt life, unscheduled downtime, low process reliability, and other issues common on receiving lines.

Benefits:

- Ideal for highly abrasive loads and long production cycles

- Designed for straight runs, inclines, and declines

- Engineered to reduce downtime and lengthen belt life

Download the Series 1750 and 1700 Flush Grid Product Highlight (PDF)

By the Numbers

Solution SpotlightThermoDrive A23 Belt Material

Hydrolysis resistant in warm or hot, humid environments, ThermoDrive A23 material provides for extended belt life with high belt-pull strength and superior product release.

Insights and Results

Snack producers find success with Intralox solutions