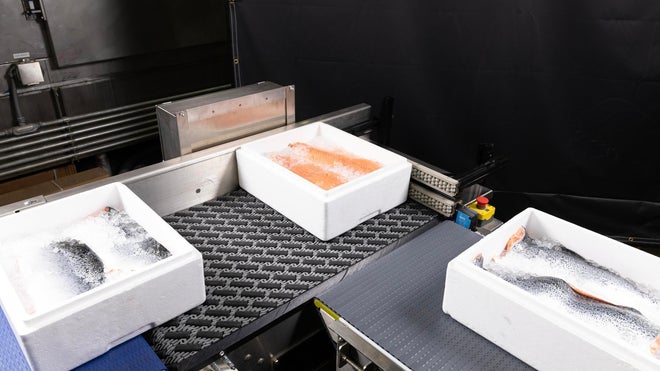

Conveyor systems for fish and seafood processing

Fish and seafood processors worldwide trust Intralox conveyor belts and solutions for every part of their operations, including receiving, processing, freezing, packaging, and more. Whether you’re out at sea or back on land, handling small shellfish, large whole fish, canned items, or filets, our industry experts can partner with you to enhance your operations.

Intralox’s fish and seafood industry solutions help you:

- Protect against Listeria, pathogens, and foreign material contamination (FMC) risks

- Safeguard food safety and product quality

- Eliminate unscheduled downtime from belt or conveyor failure

- Optimize your operations for throughput and reliability

Fish and seafood processing applications

Where can Intralox make the difference for you?

ReceivingWithstand harsh receiving line conditions with the right belting solution

Fish and seafood receiving areas have many harsh conditions, including abrasion (from sand, grit, saltwater, etc.) and heavy product loads. Conveyor belts that can’t withstand these conditions can chip or break, leading to unscheduled maintenance and downtime, FMC risks, stress, and unpredictability.

Intralox conveyor belts for fish and seafood receiving have been developed with the right combination of durability, abrasion resistance, and drainage to ensure reliability and long belt life. Consult with our industry experts to determine the exact solution best suited to your unique receiving line conditions.

Industry InsightsTop 5 Listeria Hideouts in Seafood Processing Equipment

Where could Listeria be hiding on your conveyors? We’ve created a handy tool that explains what to look for in your plant.

Insights and Results

Fish and seafood processors find success with Intralox solutions