Achieve seamless product transfers with Intralox Series 1000 Flat Top belting.

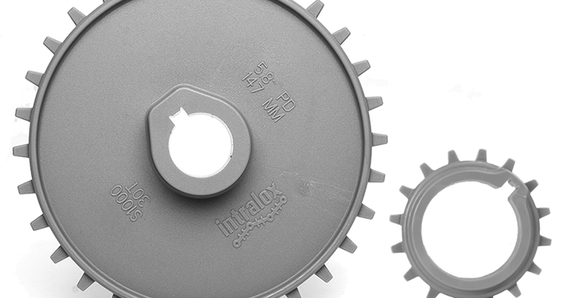

The S1000 Flat Top belt excels in applications that require smooth transfers and superior belt strength. Used across many industries—especially beverage—it features a small pitch that provides exceptional tight transfer capability and eliminates the need for dead plates.

- Bi-directional with no preferred run direction

- 0.60-in (15.2-mm) pitch reduces chordal action

- 0.75-in (19.1-mm) nose-roller transfers

| in | mm | |

| Pitch | 0.60 | 15.2 |

| Minimum Width | 3 | 76 |

| Width Increments | 0.50 | 12.7 |

| Opening Size | - | - |

| Open Area | 0% | |

| Hinge Style | Closed | |

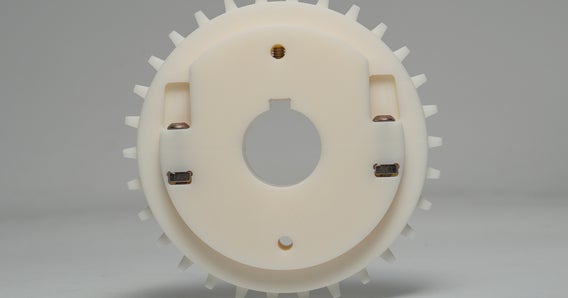

| Rod Retention; Rod Type | Barn door; unheaded | |

- Contact Intralox for precise belt measurements and stock status before designing equipment or ordering a belt.

- Smooth, closed upper surface with fully flush edges.

- Closed edges on one side of the belt.

- Underside design and small pitch allow the belt to run smoothly around nosebars.

- Lug tooth sprockets improve sprocket engagement and simplify installation.

- Small pitch reduces chordal action and the gap required at the transfer dead plate.

- Each belt material has a default rod material. Other rod materials are available. Intralox can help identify the best belt and rod material combination for your application.

- Detailed material information is provided in Product Line.

- Minimal back tension required for sprocket engagement

- Can be used over 0.75 in (19.1 mm) diameter nosebars for tight transfers.

| Belt Material | Default Rod Material, Diameter 0.18 in (4.6 mm) | Belt Strength | Temperature Range (continuous) | Belt Mass | |||

|---|---|---|---|---|---|---|---|

| lbf/ft | N/m | °F | °C | lb/ft² | kg/m² | ||

| Acetal | Polypropylene | 1,500 | 21,900 | 34 to 200 | 1 to 93 | 1.55 | 7.57 |

| Polypropylene | Polypropylene | 1,000 | 14,600 | 34 to 220 | 1 to 104 | 1.07 | 5.22 |

| Polyethylene | Polyethylene | 600 | 8,760 | -50 to 150 | -46 to 66 | 1.11 | 5.42 |

| HR nylon | Nylon | 1,000 | 14,600 | -50 to 240 | -46 to 116 | 1.31 | 6.43 |

| Document Name | Document Type | File Type | File Size |

|---|---|---|---|

| "Intralox for Tread Sorting" Application Highlight | 833 KB |