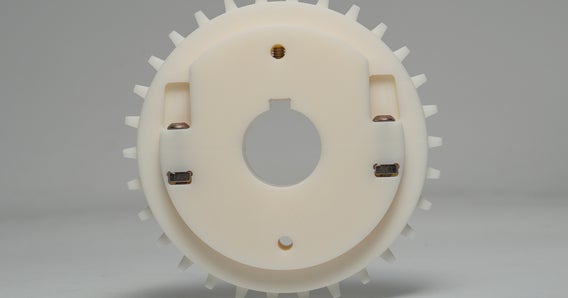

Flat Friction Top 85 mm

Series 1000Secure precise braking and metering with Intralox Series 1000 Friction Top 85 mm belting.

Designed for brake-stop and meter-spacing applications, the S1000 Flat Friction Top 85 mm belt minimizes product slippage while enabling smooth incline and decline transport. Its tight transfer capability eliminates common dead plate issues such as product skewing or jamming.

- Friction Top surface extends to belt edges

- 0.60-in (15.2-mm) pitch reduces chordal action

- 0.75-in (19.1-mm) nose-roller transfers

- 3.35-in (85-mm) minimum belt width

| in | mm | |

| Pitch | 0.60 | 15.2 |

| Minimum Width | 3.35 | 85.0 |

| Maximum Width | 66.9 | 1700 |

| Width Increments | 3.35 | 85 |

| Opening Size | - | - |

| Open Area | 0% | |

| Hinge Style | Closed | |

| Rod Retention; Rod Type | Barn door; unheaded | |

- Contact Intralox for precise belt measurements and stock status before designing equipment or ordering a belt.

- Smooth, closed upper surface with fully flush edges.

- Closed edges on one side of the belt.

- Small pitch reduces chordal action and the gap required at the transfer dead plate.

- Lug tooth sprockets improve sprocket engagement and simplify installation.

- Minimal back tension required for sprocket engagement

- Underside design combined with small pitch allows the belt to run smoothly around a 0.75 in (19 mm) nosebar. Use a dynamic nose-roller for package handling applications.

- Each belt material has a default rod material. Other rod materials are available. Intralox can help identify the best belt and rod material combination for your application.

- Detailed material information is provided in Product Line.

| Base Belt Material | Base/Friction Top | Default Rod Material, Diameter 0.18 in (4.6 mm) | Belt Strength | Temperature Range (continuous) | Belt Mass | Friction Top Hardness | Agency Acceptability | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| lbf/ft | N/m | °F | °C | lb/ft² | kg/m² | FDA (USA) | EU MC1 | ||||

| Acetal | Grey/black | Nylon | 1,500 | 21,900 | -10 to 130 | -23 to 54 | 1.80 | 8.79 | 54 Shore A | 2 | |

European Migration Certificate providing approval for food contact according to EU Regulation 10/2011.

Fully compliant