Support efficient drainage and product cooling with the Intralox Series 900 Flush Grid belt.

Used across many industries, this belt features a 38% open area that encourages fluid drainage and promotes airflow to accelerate cooling. Fully flush edges and a smooth upper surface boost worker safety, while its modular plastic construction simplifies maintenance and eases cleanability.

- 1.07-in (27.2-mm) pitch

- Approximate opening size of 0.24 in x 0.28 in (6.1 mm x 7.1 mm)

- Available in Hi-Temp material for high-heat applications

- Available with flights and sideguards

| in | mm | |

| Pitch | 1.07 | 27.2 |

| Minimum Width | 2 | 51 |

| Width Increments | 0.33 | 8.4 |

| Opening Size (approximate) | 0.24 × 0.28 | 6.1 × 7.1 |

| Open Area | 38% | |

| Hinge Style | Open | |

| Rod Retention; Rod Type | Snap-lock; headed | |

- Contact Intralox for precise belt measurements and stock status before designing equipment or ordering a belt.

- Open pattern with smooth upper surface and fully flush edges.

- Provides excellent lateral movement of containers.

- HR nylon belts use short rodlets to hold the main hinge rod in place. The rodlets are made from the same material as the main rod.

- Each belt material has a default rod material. Other rod materials are available. Intralox can help identify the best belt and rod material combination for your application.

- Detailed material information is provided in Product Line.

- Flights and sideguards are available.

- Belts made of Hi-Temp material have different minimum widths, rod type, and retention:

- Minimum width: 6 in (151 mm)

- Rod retention: occluded edge

- Rod type: unheaded

| Belt Material | Default Rod Material, Diameter 0.18 in (4.6 mm) | Belt Strength | Temperature Range (continuous) | Belt Mass | |||

|---|---|---|---|---|---|---|---|

| lbf/ft | N/m | °F | °C | lb/ft² | kg/m² | ||

| Polypropylene | Polypropylene | 700 | 10,200 | 34 to 220 | 1 to 104 | 0.76 | 3.70 |

| Enduralox polypropylene | Polypropylene | 700 | 10,200 | 34 to 220 | 1 to 104 | 0.76 | 3.70 |

| Polyethylene | Polyethylene | 350 | 5,110 | -50 to 150 | -46 to 66 | 0.81 | 3.96 |

| Acetal | Polypropylene | 1,480 | 21,600 | 34 to 200 | 1 to 93 | 1.15 | 5.62 |

| HSEC acetal | Polypropylene | 800 | 11,700 | 34 to 200 | 1 to 93 | 1.15 | 5.62 |

| Hi-Temp | Hi-Temp | 1,200 | 17,500 | 70 to 400 | 21 to 204 | 1.08 | 5.27 |

| FR TPES | Polypropylene | 750 | 10,900 | 40 to 150 | 4 to 66 | 1.19 | 5.81 |

| HR nylon | HR nylon | 1,200 | 17,500 | -50 to 240 | -46 to 116 | 1.10 | 5.40 |

| HHR nylon | HHR nylon | 1,200 | 17,500 | -50 to 310 | -46 to 154 | 1.10 | 5.40 |

| Acetal1 | Polyethylene | 1,000 | 14,600 | -50 to 70 | -46 to 21 | 1.15 | 5.62 |

| Detectable polypropylene A22 | Polypropylene | 350 | 5,110 | 0 to 150 | -18 to 66 | 0.89 | 4.35 |

Polyethylene rods can be used in cold applications when impacts or sudden starts/stops occur. Please note lower rating.

| Document Name | Document Type | File Type | File Size |

|---|---|---|---|

| S900_FlushGrid_[SideView]_(Metric).dxf | CAD Drawing | DXF | 52 KB |

| S900_FlushGrid_[TopView]_(Imperial).dxf | CAD Drawing | DXF | 335 KB |

| S900_FlushGrid_[TopView]_(Metric).dxf | CAD Drawing | DXF | 353 KB |

EZ Clean™ Polyurethane Sprocket

Series 900

Split Metal Sprocket

Series 900

Split Metal with Polyurethane (FDA) Joining Plates Reduced Clearance Sprocket

Series 900

EZ Clean™ Acetal Sprocket

Series 900

Molded Tooth Plate Split Glass-Filled Nylon Sprockets

Series 900

Dual-Tooth Nylon Split Sprockets

Series 900

Molded Acetal Sprocket

Series 900

Molded Polyurethane Sprocket

Series 900

Molded Nylon Sprocket

Series 900

Nylon Split Sprockets

Series 900

Molded Polypropylene Sprocket

Series 900

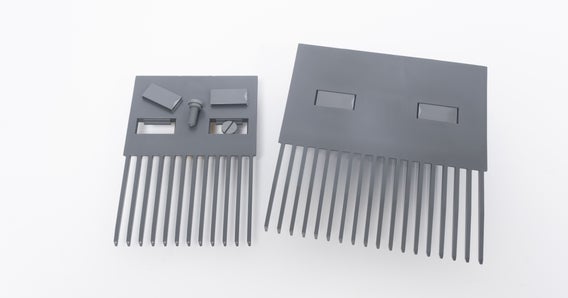

Finger Transfer Plates

Series 900

Flat Top Base Flights (Streamline Rubber)

Series 900

Flush Grid Base Flights (Streamline/No-Cling)

Series 900

Hold Down Tabs

Series 900

Flush Grid Nub Top Base Flights (Double No-Cling)

Series 900

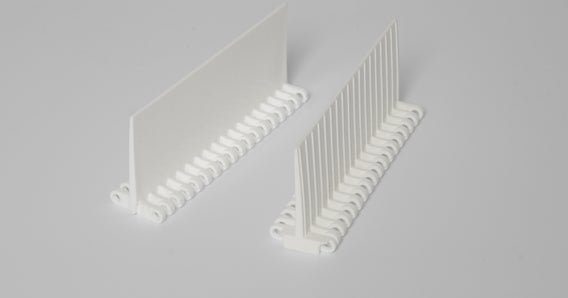

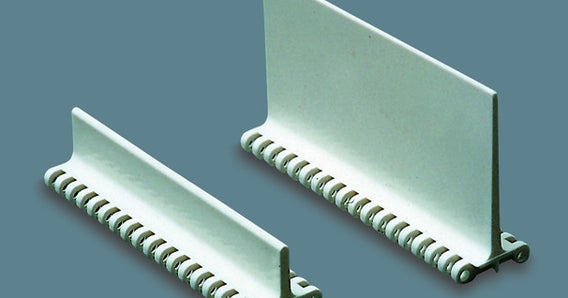

Sideguards

Series 900

Open Flush Grid, Flush Edge Base Flights (No-Cling)

Series 900

Flat Top Base Flights (Streamline)

Series 900