Secure products on slight inclines and declines with the Intralox Series 900 Flat Friction Top belt.

This belt’s rubber modules have a high-friction surface that provides superior product grip without hindering sprockets or carryways. Used across many industries, the belt is available in High Performance Friction Top (HPFT) material that withstands high temperatures and extends service life.

- HPFT material performs within a continuous temperature range of 34°F–212°F (1°C–100°C)

- Friction Top surface enables reliable operation in pan conveyance applications

- Conveys rubber tires on inclines and declines up to 30 degrees

- Minimum alternating edge indents of 1-in (25-mm) and 1.7-in (43-mm) widths

| in | mm | |

| Pitch | 1.07 | 27.2 |

| Minimum Width | 3.0 | 76 |

| Width Increments | 0.33 | 8.4 |

| Hinge Style | Open | |

| Rod Retention; Rod Type | Snap-lock; headed | |

- Contact Intralox for precise belt measurements and stock status before designing equipment or ordering a belt.

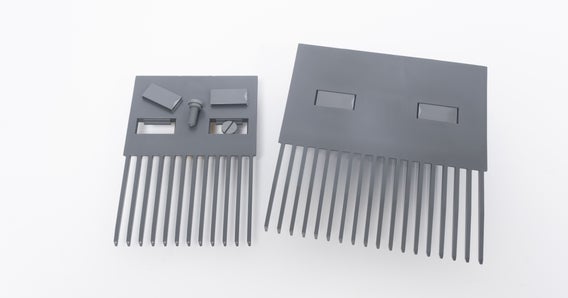

- Two-material rubber modules provide a high-friction surface without interfering with carryways and sprockets.

- Available in grey PP with black rubber and white PP with white rubber.

- Abrasion resistant rods are recommended.

- Each belt material has a default rod material. Other rod materials are available. Intralox can help identify the best belt and rod material combination for your application.

- Detailed material information is provided in Product Line.

- Not recommended for product accumulation conditions. Contact Intralox Customer Service for information about friction values between product and belt.

- When using this belt on a center-drive conveyor, it can be necessary to retain the belt laterally, by placing collars at the backbend roller before the drive.

- Temperature, environmental conditions, and product characteristics affect the effective maximum degree of incline. Consider these factors when designing conveyor systems to use these belts.

- Minimum nominal alternating edge indents: 1 in (25 mm) and 1.7 in (43 mm).

| Base Belt Material | Base/Friction Top | Default Rod Material, Diameter 0.18 in (4.6 mm) | Belt Strength | Temperature Range (continuous) | Belt Mass | Friction Top Hardness | Agency Acceptability | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| lbf/ft | N/m | °F | °C | lb/ft² | kg/m² | FDA (USA) | EU MC1 | ||||

| Polypropylene | Grey/black | Polypropylene | 1,000 | 14,600 | 34 to 150 | 1 to 66 | 1.40 | 6.83 | 45 Shore A | 2 | |

| Polypropylene | White/white | Polypropylene | 1,000 | 14,600 | 34 to 150 | 1 to 66 | 1.40 | 6.83 | 56 Shore A | 2 | 3 |

| Polypropylene | High-Performance FT blue/blue | Polypropylene | 1,000 | 14,600 | 34 to 212 | 1 to 100 | 1.40 | 6.83 | 59 Shore A | 2 | 3 |

European Migration Certificate providing approval for food contact according to EU Regulation 10/2011.

FDA compliant with restriction: Do not use in direct contact with fatty foods.

EU compliant with restriction: Do not use in direct contact with fatty foods.

| Document Name | Document Type | File Type | File Size |

|---|---|---|---|

| S900_FlatFrictionTop_[SideView]_(Imperial).dxf | CAD Drawing | DXF | 616 KB |

| S900_FlatFrictionTop_[SideView]_(Metric).dxf | CAD Drawing | DXF | 669 KB |

| S900_FlatFrictionTop_[TopView]_(Imperial).dxf | CAD Drawing | DXF | 404 KB |

| S900_FlatFrictionTop_[TopView]_(Metric).dxf | CAD Drawing | DXF | 438 KB |

EZ Clean™ Polyurethane Sprocket

Series 900

Split Metal Sprocket

Series 900

Split Metal with Polyurethane (FDA) Joining Plates Reduced Clearance Sprocket

Series 900

EZ Clean™ Acetal Sprocket

Series 900

Molded Tooth Plate Split Glass-Filled Nylon Sprockets

Series 900

Dual-Tooth Nylon Split Sprockets

Series 900

Molded Acetal Sprocket

Series 900

Molded Polyurethane Sprocket

Series 900

Molded Nylon Sprocket

Series 900

Nylon Split Sprockets

Series 900

Molded Polypropylene Sprocket

Series 900

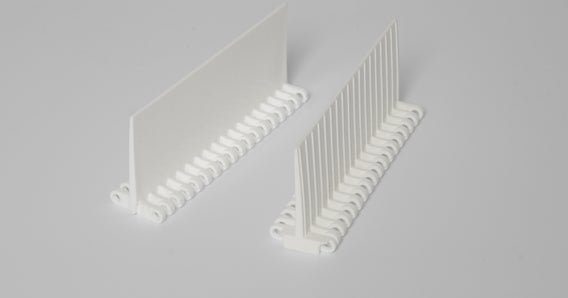

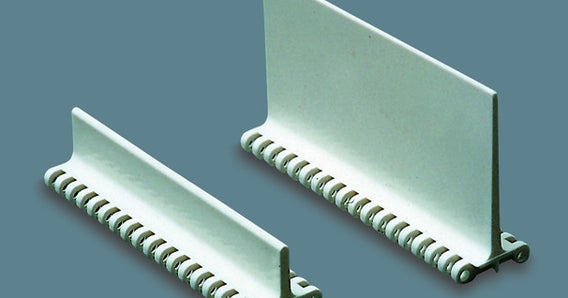

Finger Transfer Plates

Series 900

Flat Top Base Flights (Streamline Rubber)

Series 900

Flush Grid Base Flights (Streamline/No-Cling)

Series 900

Hold Down Tabs

Series 900

Flush Grid Nub Top Base Flights (Double No-Cling)

Series 900

Sideguards

Series 900

Open Flush Grid, Flush Edge Base Flights (No-Cling)

Series 900

Flat Top Base Flights (Streamline)

Series 900