Transverse Roller Top™ (TRT™)

Series 400Achieve smooth 90-degree product transfers with the Intralox Series 400 Transverse Roller Top (TRT) belt.

Originally designed for tire sortation and merging, this belt features acetal rollers that enable controlled side-to-side product movement and transfers. Its modular design simplifies repairs and maintenance, while its stainless-steel axles provide durability.

- Fully flush edges

- 0.70-in (17.8-mm) roller diameter

- Refer to Intralox S4400 TRT belting for our advanced solution

| in | mm | |

| Pitch | 2.00 | 50.8 |

| Minimum Width | 6 | 152 |

| Width Increments | 2.00 | 50.8 |

| Opening Size (approximate) | - | - |

| Open Area | 18% | |

| Hinge Style | Closed | |

| Rod Retention; Rod Type | Slidelox; unheaded | |

- Contact Intralox for precise belt measurements and stock status before designing equipment or ordering a belt.

- Flush edges.

- Uses acetal rollers.

- Stainless steel axles provide durability and long-lasting performance.

- Slidelox are glass-reinforced polypropylene.

- Each belt material has a default rod material. Other rod materials are available. Intralox can help identify the best belt and rod material combination for your application.

- Detailed material information is provided in Product Line.

- Designed for 90-degree transfers.

- For stronger belt performance, see S4400 Transverse Roller Top.

- Roller diameter: 0.70 in (17.8 mm).

- Roller length: 0.825 in (20.9 mm).

- Roller spacing: 2 in (50.8 mm).

- Standard roller indent: 0.90 in (23 mm).

- Distance to centerline of first roller: 1.3 in (33 mm).

- Spacing between first and second roller: 1.8 in (46 mm).

- Spacing between all other rollers: 2 in (50.8 mm).

| Belt Material | Default Rod Material, Diameter 0.24 in (6.1 mm) | Belt Strength | Temperature Range (continuous) | Belt Mass | |||

|---|---|---|---|---|---|---|---|

| lbf/ft | N/m | °F | °C | lb/ft² | kg/m² | ||

| Polypropylene | Nylon | 2,200 | 32,100 | 34 to 200 | 1 to 93 | 2.44 | 11.94 |

| Document Name | Document Type | File Type | File Size |

|---|---|---|---|

| S400_TransverseRollerTop_FlushEdge_Slidelox_4inch_(Imperial).dxf | CAD Drawing | DXF | 100 KB |

| S400_TransverseRollerTop_FlushEdge_Slidelox_4inch_(Metric).dxf | CAD Drawing | DXF | 114 KB |

| S400_TransverseRollerTop_FlushEdge_Slidelox_6inch_(Imperial).dxf | CAD Drawing | DXF | 138 KB |

| S400_TransverseRollerTop_FlushEdge_Slidelox_6inch_(Metric).dxf | CAD Drawing | DXF | 155 KB |

| S400_TransverseRollerTop_Interior_4inch_(Imperial).dxf | CAD Drawing | DXF | 211 KB |

| S400_TransverseRollerTop_Interior_4inch_(Metric).dxf | CAD Drawing | DXF | 228 KB |

| S400_TransverseRollerTop_Interior_6inch_(Imperial).dxf | CAD Drawing | DXF | 308 KB |

| S400_TransverseRollerTop_Interior_6inch_(Metric).dxf | CAD Drawing | DXF | 343 KB |

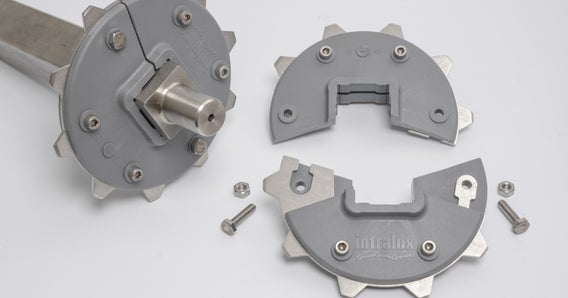

Split Metal Sprocket

Series 400

Split Low Back Tension Ultra Abrasion Resistant Polyurethane Sprocket

Series 400

Molded Tooth Plate Split Low Back Tension Polyurethane Composite Sprockets

Series 400

Molded Tooth Plate Split Polyurethane Composite Sprockets

Series 400

Split Ultra Abrasion Resistant Polyurethane Sprockets

Series 400

HR Nylon Sprockets

Series 400

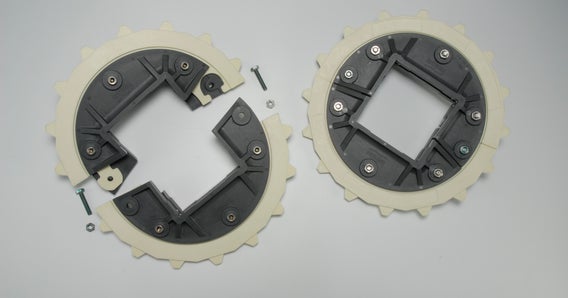

HR Nylon Split Sprockets

Series 400

Molded Sprocket

Series 400

Split Metal with Polyurethane (FDA) Joining Plates Reduced Clearance Sprockets

Series 400

Split Support Wheel

Series 400

Hold Down Tabs

Series 400

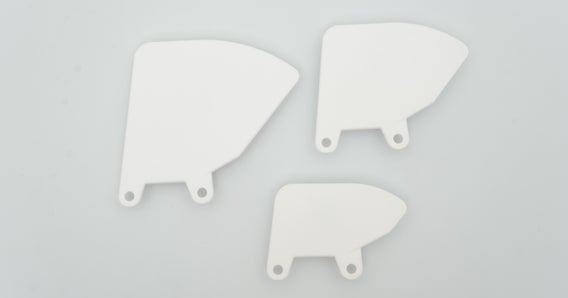

Two-Material Finger Transfer Plates

Series 400

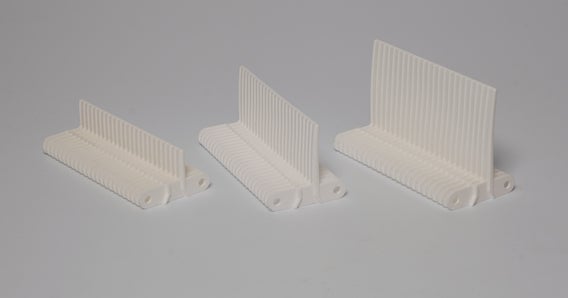

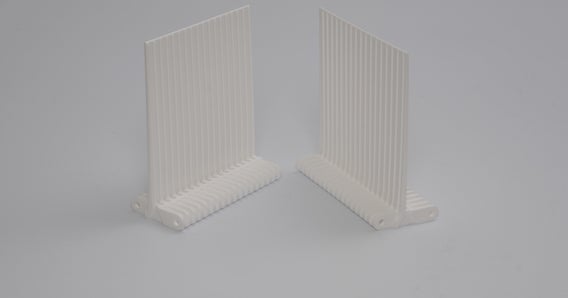

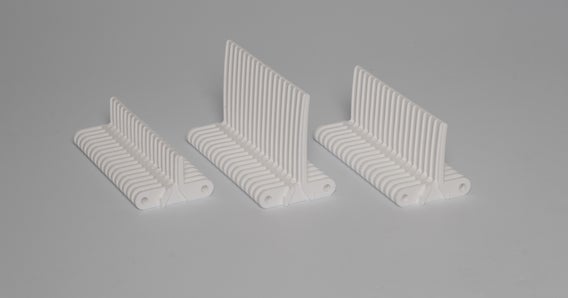

Sideguards

Series 400

Finger Transfer Plates

Series 400

Self-Clearing Finger Transfer Plates

Series 400

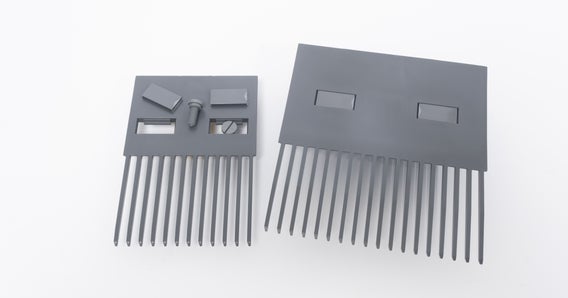

Open Hinge Base Flights (Streamline/No-Cling)

Series 400

Flush Grid Base Flights (Double No-Cling)

Series 400

Insert Nuts

Series 400

Flat Top Base Flights (Streamline)

Series 400

Flush Grid Base Flights (Streamline/No-Cling)

Series 400