Support efficient product accumulation in industrial applications with the Intralox Series 400 Roller Top belt.

Used especially to convey tires, wheel assemblies, and seats in tire and automotive plants, this belt features rollers that enable low back pressure accumulation on continuous lines. A cost-saving retrofit for existing roller conveyors, it drastically reduces line jams and eliminates the need for lubrication.

- Fully flush edges

- Acetal rollers rotate in the direction of belt travel

- Slidelox rod retention system eases maintenance

| in | mm | |

| Pitch | 2.00 | 50.8 |

| Minimum Width | 6 | 152 |

| Width Increments | 2.00 | 50.8 |

| Opening Size | - | - |

| Open Area | 18% | |

| Hinge Style | Closed | |

| Rod Retention; Rod Type | Slidelox; unheaded | |

- Contact Intralox for precise belt measurements and stock status before designing equipment or ordering a belt.

- Flush edges.

- Uses acetal rollers.

- Uses stainless steel axles.

- Slidelox are glass-reinforced polypropylene.

- Each belt material has a default rod material. Other rod materials are available. Intralox can help identify the best belt and rod material combination for your application.

- Detailed material information is provided in Product Line.

- Allows for low back pressure accumulation.

- Roller diameter: 0.70 in (17.8 mm).

- Roller length: 0.825 in (20.9 mm).

- Standard roller indent: 0.90 in (23 mm)

- Distance to centerline of first roller: 1.3 in (33 mm)

- Spacing between first and second roller: 1.8 in (46 mm).

- Spacing between all other rollers: 2 in (50.8 mm).

- Compatible with Intralox belt tensioners. See Intralox Belt Tensioners for more information.

| Belt Material | Default Rod Material, Diameter 0.24 in (6.1 mm) | Belt Strength | Temperature Range (continuous) | Belt Mass | |||

|---|---|---|---|---|---|---|---|

| lbf/ft | N/m | °F | °C | lb/ft² | kg/m² | ||

| Polypropylene | Nylon | 2,200 | 32,100 | 34 to 200 | 1 to 93 | 2.44 | 11.94 |

| Acetal | Nylon | 3,000 | 43,800 | -50 to 200 | -46 to 93 | 3.36 | 16.41 |

| Document Name | Document Type | File Type | File Size |

|---|---|---|---|

| S400 Roller Top for Automotive Application Highlight | 810 KB | ||

| S400_RollerTop_FlushEdge_Slidelox_4inch_(Imperial).dxf | CAD Drawing | DXF | 101 KB |

| S400_RollerTop_FlushEdge_Slidelox_4inch_(Metric).dxf | CAD Drawing | DXF | 111 KB |

| S400_RollerTop_FlushEdge_Slidelox_6inch_(Imperial).dxf | CAD Drawing | DXF | 144 KB |

| S400_RollerTop_FlushEdge_Slidelox_6inch_(Metric).dxf | CAD Drawing | DXF | 153 KB |

| S400_RollerTop_Interior_4inch_(Imperial).dxf | CAD Drawing | DXF | 211 KB |

| S400_RollerTop_Interior_4inch_(Metric).dxf | CAD Drawing | DXF | 223 KB |

| S400_RollerTop_Interior_6inch_(Imperial).dxf | CAD Drawing | DXF | 309 KB |

| S400_RollerTop_Interior_6inch_(Metric).dxf | CAD Drawing | DXF | 318 KB |

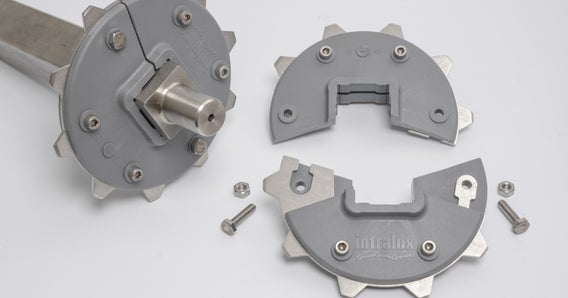

Split Metal Sprocket

Series 400

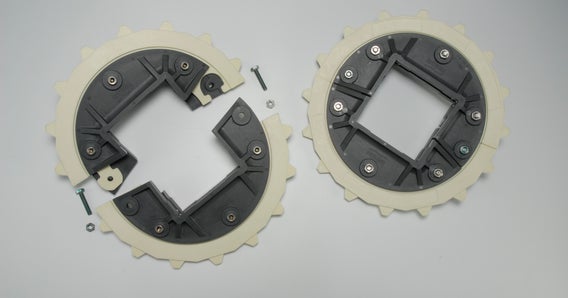

Molded Tooth Plate Split Low Back Tension Polyurethane Composite Sprockets

Series 400

Split Low Back Tension Ultra Abrasion Resistant Polyurethane Sprocket

Series 400

Molded Tooth Plate Split Polyurethane Composite Sprockets

Series 400

Split Ultra Abrasion Resistant Polyurethane Sprockets

Series 400

HR Nylon Sprockets

Series 400

HR Nylon Split Sprockets

Series 400

Molded Acetal Sprocket

Series 400

Split Metal with Polyurethane (FDA) Joining Plates Reduced Clearance Sprockets

Series 400

Molded Polyurethane Sprocket

Series 400

Molded Polypropylene Sprocket

Series 400

Split Support Wheel

Series 400

Hold Down Tabs

Series 400

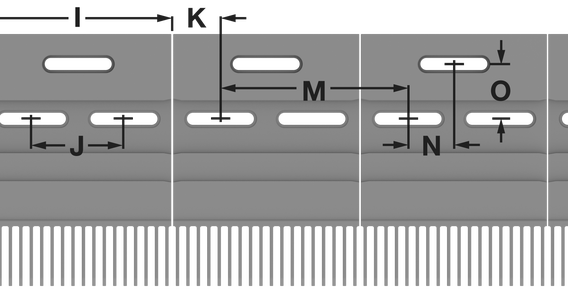

Dimensional Requirements for S400 Self-Clearing Finger Transfer Plate Installation

Series 400

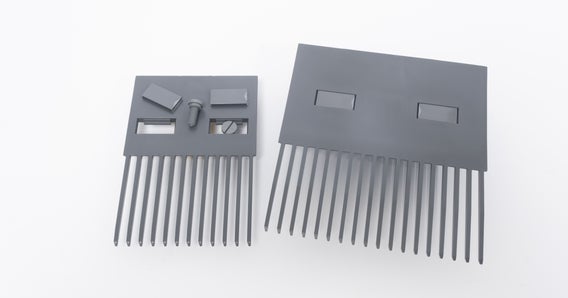

Two-Material Finger Transfer Plates

Series 400

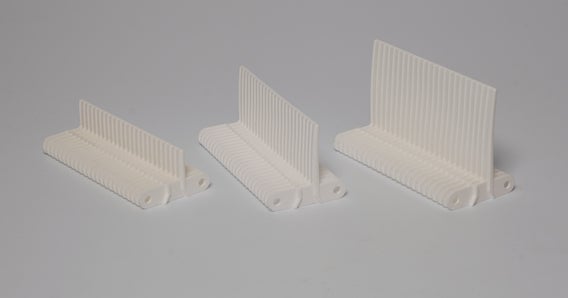

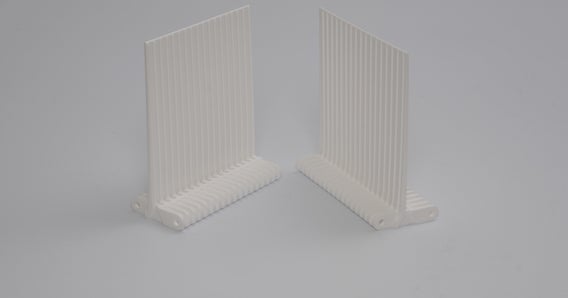

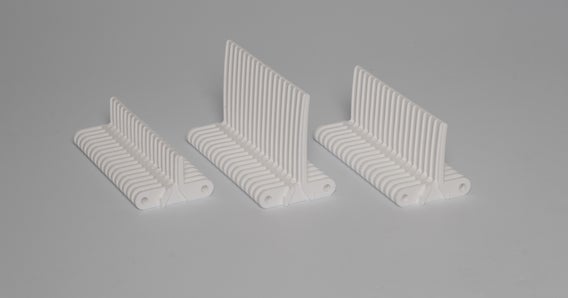

Sideguards

Series 400

Finger Transfer Plates

Series 400

Self-Clearing Finger Transfer Plates

Series 400

Open Hinge Base Flights (Streamline/No-Cling)

Series 400

Flush Grid Base Flights (Double No-Cling)

Series 400

Insert Nuts

Series 400

Flat Top Base Flights (Streamline)

Series 400

Flush Grid Base Flights (Streamline/No-Cling)

Series 400