Simpler. Stronger. Safer.

Belts and materials designed to solve a wide range of food safety challenges

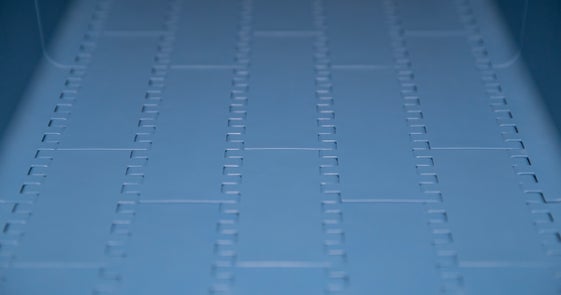

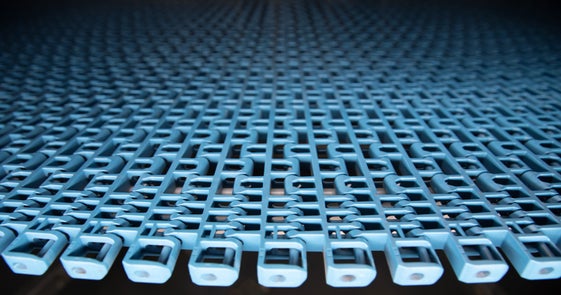

Food-Safe Modular Plastic Belting

Increase uptime and throughput without fear of belt-related foreign material risks.

Your ability to guarantee the quality and safety of your products is more important than ever. Intralox® FoodSafe™ conveyor belts allow food processors to take a proactive approach to food safety without sacrificing operational efficiency.

With an array of belt materials and designs—engineered to tackle foreign material risks head-on—Intralox FoodSafe belting helps ensure uncompromised food safety, product quality, and brand integrity. When combined with the comprehensive expertise and services of our Intralox FoodSafe portfolio, these food-grade conveyor belts deliver optimal performance in direct food contact applications.

Benefits

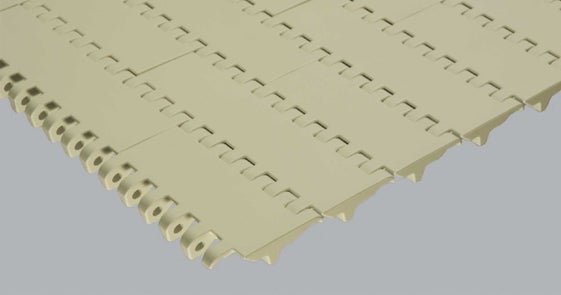

- Prevent breakage caused by belt mishandling

- Maximize belt life in high-impact or abrasive applications

- Increase safeguards with detectable materials

- Maintain belt strength and durability in high-chemical-exposure applications

Belt Options

Where can our food-safe modular plastic belting deliver value for you?