S8050 Flat Top E (7.0 mm) Polyurethane A23

Series 8050Substantially extend belt life in challenging direct food–contact applications with the Intralox Series 8050 Flat Top (7.0 mm) belt in A23.

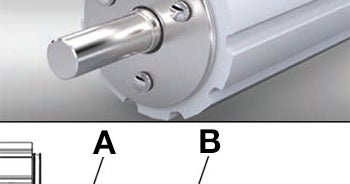

Part of our BarDrive product line, this belting features a full-width drive bar that maximizes belt pull. Its tensionless, positive-drive system reduces downtime and eases maintenance in heavily loaded, direct food–contact applications.

Warm, humid conditions in food processing can strain conventional polyurethane belts, shortening their service lives. This belt is made of A23: a unique polyurethane material offering unparalleled hydrolysis resistance that significantly extends belt life. With a sink-free surface, it excels in applications that require superior product release, including snack and pet food processing.

- Pair with Intralox ZeroSplice technology to eliminate splicing needs

- Homogeneous thermoplastic structure streamlines installation

- Lightweight, hinge-free belting improves sanitation

- Performs within a continuous temperature range of 32°F–212°F (0°C–100°C)

| in | mm | ||||

| Pitch | 1.956 | 50 | |||

| Overall Thickness | 0.276 | 7.0 | |||

| Minimum Width | 1 | 25 | |||

| Maximum Width | 72 | 1,829 | |||

| Minimum Backbend Diameter1 | 5.2 | 132 | |||

| Minimum Sprocket Diameter (8T)2 | 5.2 | 132 | |||

| Open Area (seamless surface) | 0% | ||||

| Available Joining Options | prepared ends, ThermoLace HDE, endless, metal lace | ||||

| Available Colors | blue, white | ||||

For belt only, not including accessories such as Synchronized Sidewalls and flights.

For belt only, not including accessories such as Synchronized Sidewalls and flights.

- Contact Intralox for precise belt measurements and stock status before designing equipment or ordering a belt.

- Designed to perform well in hydrolysis prone applications.

- Available with flights and sidewall.

- For continuous use from 32°F (0°C) to 212°F (100°C) with these exceptions:

- For temperatures over 140°F (60°C), contact Intralox Customer Service with application information.

- For use below 32°F (0°C), contact Intralox Customer Service for minimum sprocket diameter and other considerations.

- See Material Compliance for compliance details.

| Belt Material | Maximum Belt Pull Capability1,2 | Temperature Range (continuous)3 | Belt Weight | |||

|---|---|---|---|---|---|---|

| lbf/ft width | N/m width | °F | °C | lb/ft2 | kg/m2 | |

| PUR A23 | 540 | 7880 | See Product Notes in the previous table. | 0.804 | 3.93 | |

With sprockets spaced on 3 in (76 mm) centers; Consider using stacked sprockets for optimal operational performance in heavily loaded applications

For continuous use over 100°F (38°C), contact Intralox Customer Service for actual belt capability.

For temperatures below 32°F (0°C) or higher than 212°F (100°C), contact Intralox Customer Service.

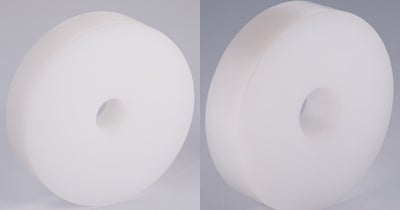

S8050 EZ Clean No-Lace Machined Acetal Sprocket Data

Series 8050

S8050 EZ Clean Machined Acetal Sprocket Data

Series 8050

S8050 Natural Acetal Buildup Resistant Sprocket Data

Series 8050

S8050 EZ Clean Molded Acetal Sprocket Data

Series 8050

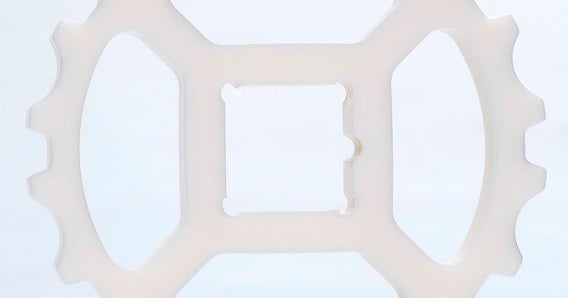

S8050 Split Sprocket Data,

Series 8050

Full Width Sprocket,

Series 8050

S8050 EZ Clean Machined Nylon Sprocket Data

Series 8050