Improve product release in conditioning applications with Intralox Series 2900 Curved Top belts.

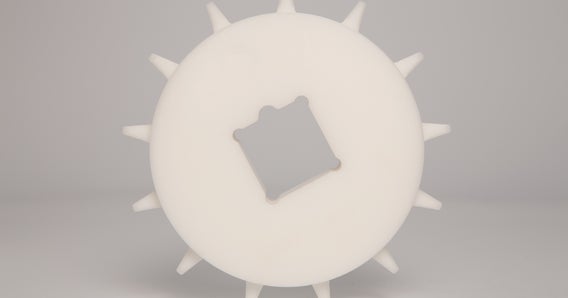

Part of our revolutionary DirectDrive System, S2900 Curved Top belting brings exceptional product release to spiral freezing, cooling, and proofing applications. The belt’s surface design enables smooth transfers, and its lack of chordal action optimizes scraper placement for release of challenging products such as fish, poultry, or raw dough.

- Reliably smooth DirectDrive technology gently handles delicate products

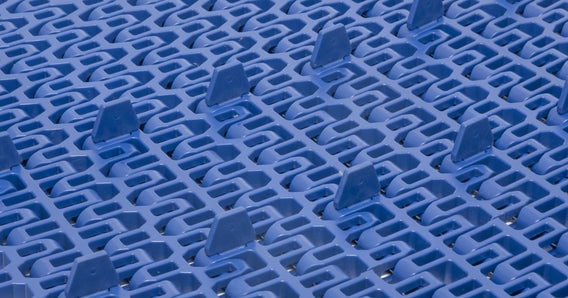

- Curved Top design enables superior product release and smooth infeed and outfeed transfers

- Continuous belting curvature around sprockets allows scrapers to be placed closer to the belt

- Open belt area improves product conditioning and simplifies cleaning

| in | mm | |

| Pitch | 1.5 | 38.1 |

| Minimum Width | 13.5 | 342.9 |

| Maximum Width | 61.7 | 1,567 |

| Width Increments | 1.0 | 25.4 |

| Opening Size (approx.) | 0.52 x 0.39 | 16.7 x 13.5 |

| Open Area | 44% | |

| Minimum Open Area | 26% | |

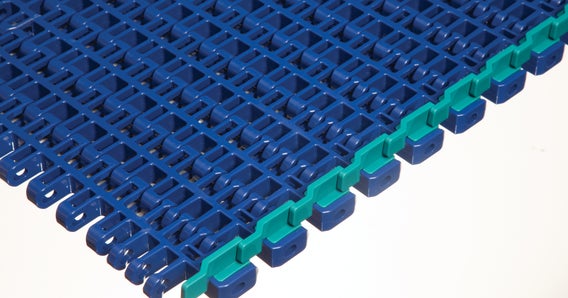

| Hinge Style | Closed | |

| Rod Retention; Rod Type | Occluded edge; unheaded | |

- This belt has pinch points. See the Safety section in the Intralox Conveyor Belting Installation, Maintenance & Troubleshooting Manual for more information.

- Contact Intralox for precise belt measurements and stock status before designing equipment or ordering a belt.

- Width dimension includes tooth protrusion

- Belt openings pass straight through the belt to simplify cleaning.

- Robust edge feature adds strength to the outside belt edge

- Relatively uniform open area across the belt width to aid product freezing and cooling

- The curved top surface is consistent across the belt width except for the sideguard locations at the belt edges.

- Continuous curvature of belt surface when wrapped around sprockets.

- Cooling channels across the belt width aid in product conditioning and fluid drainage.

- Detailed material information is provided in Product Line.

- Detailed conveyor design guidelines are available. Contact Intralox Customer Service for more information.

- Contact Intralox Customer Service for preferred run direction on spiral applications.

- Minimum sprocket indent from the inside belt edge and from the outside belt edge can vary. Contact Intralox Customer Service to determine exact placement.

| Belt Material | Default Rod Material, Diameter 0.12 in (3 mm) | Belt Strength1 | Spiral Belt Strength2 | Temperature Range (continuous) | Belt Mass | ||||

|---|---|---|---|---|---|---|---|---|---|

| lbf/ft | N/m | lbf/ft | N/m | °F | °C | lb/ft² | kg/m² | ||

| Acetal | Acetal | 1,600 | 23,400 | 475 | 2,110 | -50 to 200 | -46 to 93 | 1.92 | 9.35 |

Not designed for use in straight-running applications

Intralox engineers are available to provide an accurate comparison of spiral belt strengths. Contact Intralox Customer Service for more information.

| Document Name | Document Type | File Type | File Size |

|---|---|---|---|

| Series 2900 Curved Top Product Highlight | 654 KB |