| in | mm | |

| Pitch | 1.00 | 25.4 |

| Minimum Width | 7 | 178 |

| Width Increments | 0.50 | 12.7 |

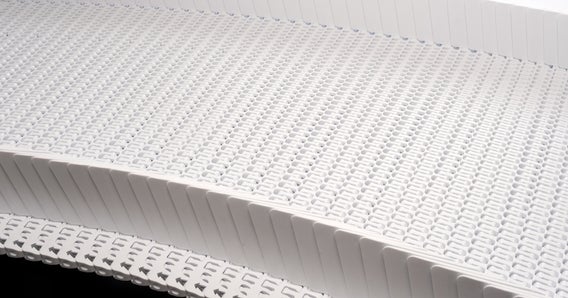

| Opening Size (approximate) | 0.35 × 0.30 | 8.9 × 7.6 |

| Open Area | 42% | |

| Product Contact Area | 23% | |

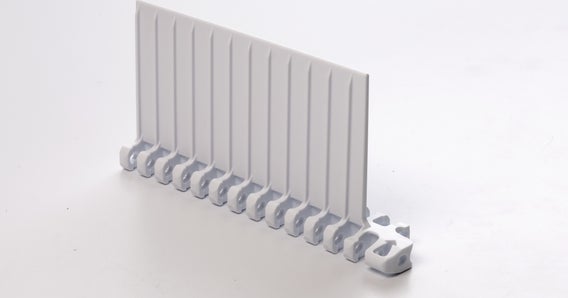

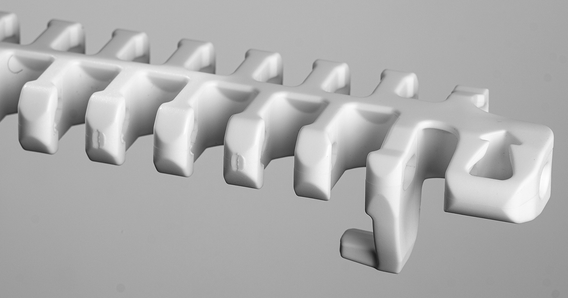

| Hinge Style | Open | |

| Rod Retention; Rod Type | Occluded edge; unheaded | |

- Contact Intralox for precise belt measurements and stock status before designing equipment or ordering a belt.

- Belt openings pass straight through the belt to simplify cleaning.

- Available with tight turning modules built into one or both sides of the belt and inside 1.7 modules and outside 2.2 modules to improve belt strength.

- Each belt material has a default rod material. Other rod materials are available. Intralox can help identify the best belt and rod material combination for your application.

- Detailed material information is provided in Product Line.

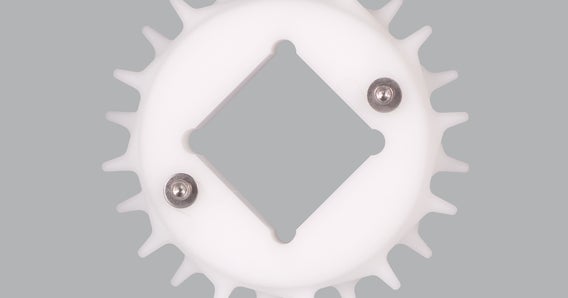

- Sprocket drive system is designed to minimize wear and require low return-side tension.

- Contact Intralox Customer Service before using a belt width greater than 18 in (457 mm) in spiral and flat turning applications.

- Designed for sideflexing applications with a standard turn radius of 1.7 times belt width (measured from inside edge) for belt widths up to 18 in (457 mm).

- For belt widths over 18 in (457 mm) to 24 in (610 mm), the standard turn radius is 1.8 times the belt width.

- For belt widths over 24 in (610 mm) to 30 in (762 mm), the standard turn radius is 2.0 times the belt width.

- For belt widths over 30 in (762 mm) to 36 in (914 mm), the standard turn radius is 2.2 times the belt width.

- Radius belt wearstrips are available.

- Looking in the direction of flat-turning travel, the minimum sprocket indent from the right side belt edge with tight turning modules is 2.625 in (66.7 mm).

- Minimum sprocket indent from the left side belt edge with tight turning modules: 2.875 in (73 mm).

- Minimum nosebar diameter: 1.375 in (34.9 mm).

| Belt Material | Default Rod Material, Diameter 0.18 in (4.6 mm) | Straight Belt Strength | Curved Belt Strength | Temp. Range (continuous) | Belt Mass | ||||

|---|---|---|---|---|---|---|---|---|---|

| lbf/ft | N/m | °F | °C | lb/ft² | kg/m² | ||||

| Polypropylene | Acetal | 600 | 8,760 | For curved belt strength calculations, contact Intralox Customer Service. | 34 to 200 | 1 to 93 | 1.20 | 5.86 | |

| Acetal | Nylon | 600 | 8,760 | -50 to 200 | -46 to 93 | 1.73 | 8.44 | ||

| Polypropylene | Polypropylene1 | 600 | 8,760 | 34 to 220 | 1 to 104 | 1.12 | 5.47 | ||

Polypropylene rods can be installed in polypropylene belts when extra chemical resistance is required. Please note lower belt strength.

| Document Name | Document Type | File Type | File Size |

|---|---|---|---|

| PK Belt Material Product Highlight | 444 KB | ||

| S2400_TightTuning_FlushEdge_7.125inch_(Metric).dxf | CAD Drawing | DXF | 729 KB |

| S2400_TightTurning_FlushEdge_13.125inch[SpiralModule]_(Imperial).dxf | CAD Drawing | DXF | 2 MB |

| S2400_TightTurning_FlushEdge_13.125inch[SpiralModule]_(Metric).dxf | CAD Drawing | DXF | 2 MB |

| S2400_TightTurning_FlushEdge_7.125inch_(Imperial).dxf | CAD Drawing | DXF | 712 KB |

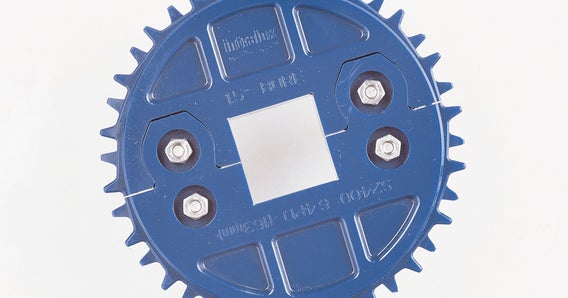

Acetal Split Sprockets

Series 2400

Glass-Filled Nylon Split Sprockets

Series 2400

HR Nylon EZ Clean™ Sprockets

Series 2400

Split Natural Nylon (FDA) Sprockets

Series 2400

Molded Glass-Filled Nylon Sprockets

Series 2400

Molded Acetal Sprocket

Series 2400

Split Ultra Abrasion Resistant Polyurethane Sprockets

Series 2400

CleanLock™ Acetal

Series 2400

Molded Polyurethane Sprockets

Series 2400

Nylon (FDA) Sprockets

Series 2400