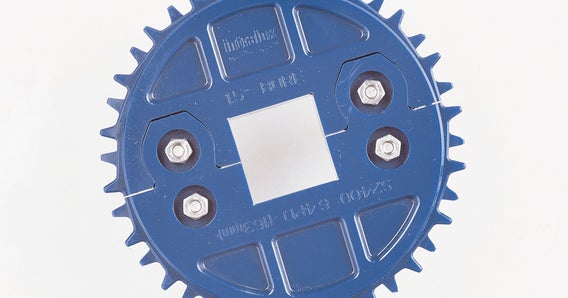

Radius Flush Grid with Heavy-Duty Edge

Series 2400Minimize foreign material concerns and increase belt life with the most hygienic, durable radius belt in the food industry.

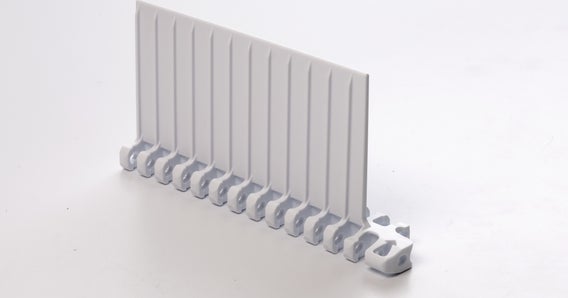

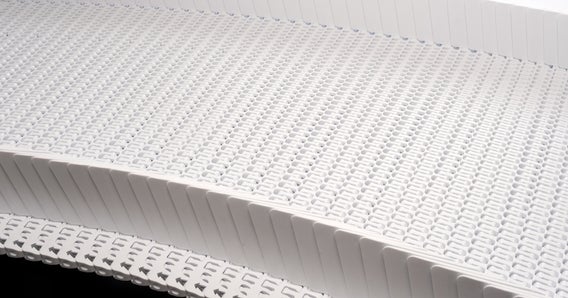

The Intralox Series 2400 Radius Flush Grid with Heavy-Duty Edge (HDE) belt is the food industry’s most snag-resistant radius belt with the longest lasting fatigue life. Its fault-tolerant edge design minimizes edge breakage to maximize uptime, minimize product contamination risks, and extend belt life, regardless of plant, production, or maintenance conditions.

- Patented Load-Sharing edge design improves load sharing across links, reducing stress in critical areas

- Direct retrofit with legacy S2400 belts—no need to change sprockets, designs, or drawings

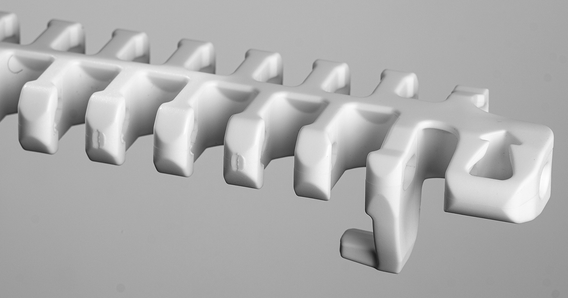

- Arrows on belt edge indicate direction of belt run (patent-pending design)

- Each module has a directional arrow design cue

- Smaller belt edge opening area and sculpted module features increase safety and reduce catchpoints

| in | mm | |

| Pitch | 1.0 | 25.4 |

| Minimum Width | 4.0 | 101.6 |

| Width Increments | 0.50 | 12.7 |

| Opening Size (approximate) | 0.35 x 0.30 | 8.9 x 7.6 |

| Open Area | 42% | |

| Hinge Style | Open | |

| Rod Retention; Rod Type | Occluded edge; unheaded | |

- Contact Intralox for precise belt measurements and stock status before designing equipment or ordering a belt.

- Heavily reinforced and carefully sculpted edge is designed to resist belt snagging and edge damage while maintaining cleanability.

- Flush edge features an intuitive molded-in arrow to indicate preferred run direction, and extensions to reduce finger entrapment.

- Load-Sharing™ belt edge improves how the load is shared and minimizes belt fatigue failure.

- Belt openings pass straight through the belt to simplify cleaning.

- Each belt material has a default rod material. Other rod materials are available. Intralox can help identify the best belt and rod material combination for your application.

- Detailed material information is provided in Product Line.

- Designed for radius applications with a turn radius of 2.2 times the belt width (measured from the inside edge).

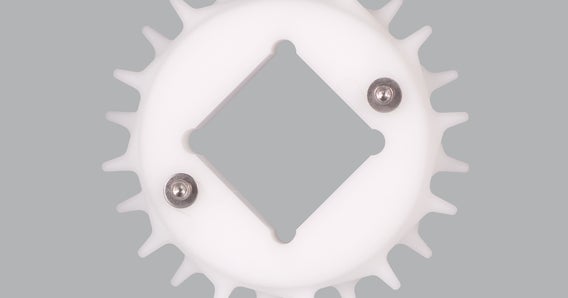

- Sprocket drive system minimizes wear and requires low return-side tension.

- Contact Intralox Customer Service before using a belt wider than 36 in (914 mm) in flat-turning or spiral applications.

- Temperature, environmental conditions, and product characteristics affect the maximum degree of incline. Consider these factors when designing conveyor systems using these belts.

- Available with hold down guides

- Radius belt wearstrips are available.

- Minimum nosebar diameter: 1.375 in (34.9 mm).

| Base Belt Material | Default Rod Material, Diameter 0.18 in (4.6 mm) | Straight Belt Strength | Curved Belt Strength | Temp. Range (continuous)1 | Belt Mass | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| lbf/ft | N/m | °F | °C | lb/ft² | kg/m² | ||||||||

| Polypropylene | PK | 1,200 | 17,500 | For curved belt strength calculations, contact Intralox Customer Service. | 34 to 176 | 1 to 80 | 1.10 | 5.37 | |||||

| Acetal | PK | 1,700 | 24,800 | -40 to 176 | -40 to 80 | 1.59 | 7.7624 | ||||||

| HR Nylon | HR Nylon | 1,700 | 24,800 | -50 to 240 | -46 to 116 | 1.43 | 6.98 | ||||||

| PK | PK | 1,700 | 24,800 | -40 to 176 | -40 to 80 | 1.4 | 6.8348 | ||||||

Sideflexing applications must not exceed 180°F (82°C).

| Document Name | Document Type | File Type | File Size |

|---|---|---|---|

| PK Belt Material Product Highlight | 444 KB | ||

| Series 2400 Radius with Heavy Duty Edge Product Highlight | 640 KB |

Acetal Split Sprockets

Series 2400

Glass-Filled Nylon Split Sprockets

Series 2400

HR Nylon EZ Clean™ Sprockets

Series 2400

Split Natural Nylon (FDA) Sprockets

Series 2400

Molded Glass-Filled Nylon Sprockets

Series 2400

Molded Acetal Sprocket

Series 2400

Split Ultra Abrasion Resistant Polyurethane Sprockets

Series 2400

CleanLock™ Acetal

Series 2400

Molded Polyurethane Sprockets

Series 2400

Nylon (FDA) Sprockets

Series 2400