Overcome challenging conditions in pan-area applications with a powerful, magnetic solution.

The Intralox Series 1400 4.5-in Mold to Width (MTW) Flat Top ProTrax belt with Tabs is magnetic double-strand belting for pan inclines, declines, vertical switches, and more. Specially designed for bakery plants, its plastic surface significantly reduces pan wear—a common steel chain side effect—extending pan life and reducing replacement costs.

- Provides stable performance with an extraordinary belt life, even in hot, dry, and oily environments

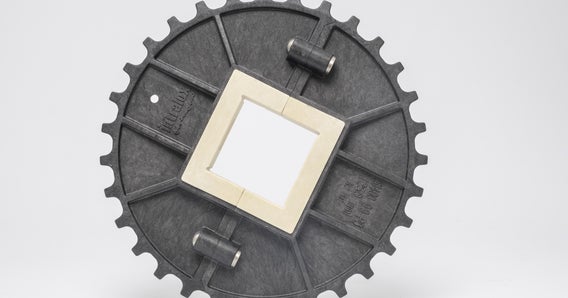

- Alternating rows of magnetic modules and S1400 MTW Flat Top modules

- Strong, rare-earth magnets provide support in multiple applications

- Reliable incline/decline performance in angles up to 30 degrees

| in | mm | |

| Pitch | 1.00 | 25.4 |

| Molded Widths | 4.5 | 114.3 |

| Opening Size (approximate) | - | - |

| Open Area | 0% | |

| Hinge Style | Closed | |

| Rod Retention; Rod Type | Slidelox; unheaded | |

- Contact Intralox for precise belt measurements and stock status before designing equipment or ordering a belt.

- Powerful magnets are embedded in the belts. Contact Intralox Customer Service for guidance on how temperature affects magnet strength.

- The standard belt configuration consists of magnetic modules and S1400 Raised Flat Top modules alternating every other row to maximize wear resistance.

- Molded with robust tracking tabs to support the belt in heavy side-loading applications

- Tabs fit into a straight track style carryway with 1.75 in (44.5 mm) spacing.

- Slidelox provide rod and cap retention.

- Each belt material has a default rod material. Other rod materials are available. Intralox can help identify the best belt and rod material combination for your application.

- Detailed material information is provided in Product Line.

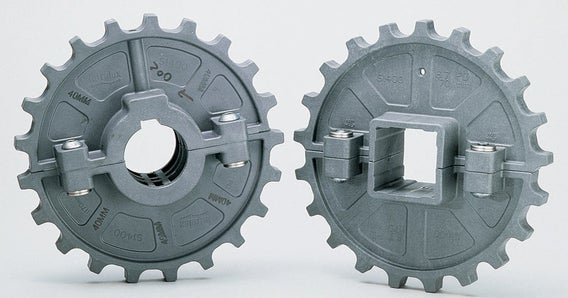

- Needs only one drive sprocket and one idle sprocket per belt strand.

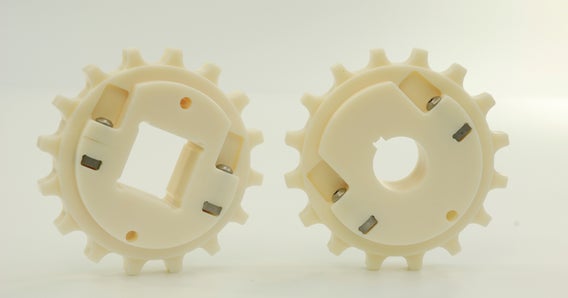

- Sprockets are all plastic with stainless steel fasteners and large, lug-style teeth for excellent durability and wear life.

- Most sprockets feature a split design so shafts do not have to be removed for retrofits and changeovers.

- Ideal for incline, decline, vertical switch, pan indexing, and metering applications.

- Install belt strands to run in the same direction.

- Determine belt spacing based on maximum surface area contact with the bottom surface of the conveyed product.

| Belt Material | Default Rod Material, Diameter 0.18 in (4.6 mm) | Belt Strength | Temperature Range (continuous) | Belt Mass | |||

|---|---|---|---|---|---|---|---|

| lbf | N | °F | °C | lb/ft | kg/m | ||

| Acetal | Nylon | 550 | 2,450 | -50 to 200 | -46 to 93 | 1.46 | 2.18 |

| HHR nylon | HHR Nylon | 550 | 2,450 | -50 to 310 | -46 to 154 | 1.296 | 1.95 |