| in | mm | |

| Pitch | 1.00 | 25.4 |

| Minimum Width | 5 | 127 |

| Width Increments | 1.00 | 25.4 |

| Open Area | 0% | |

| Hinge Style | Closed | |

| Rod Retention; Rod Type | Slidelox; unheaded | |

- Contact Intralox for precise belt measurements and stock status before designing equipment or ordering a belt.

- Fully flush edges.

- Available in grey polypropylene with black rubber.

- Slidelox are available in polypropylene or acetal.

- Each belt material has a default rod material. Other rod materials are available. Intralox can help identify the best belt and rod material combination for your application.

- Detailed material information is provided in Product Line.

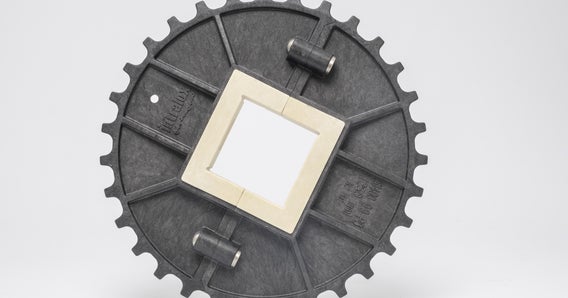

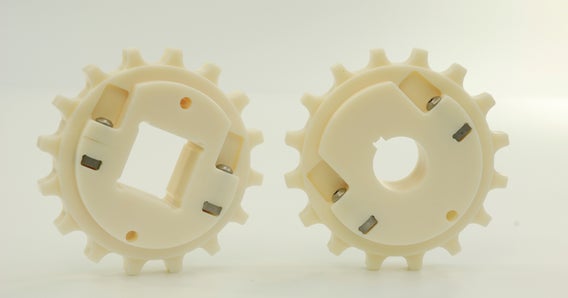

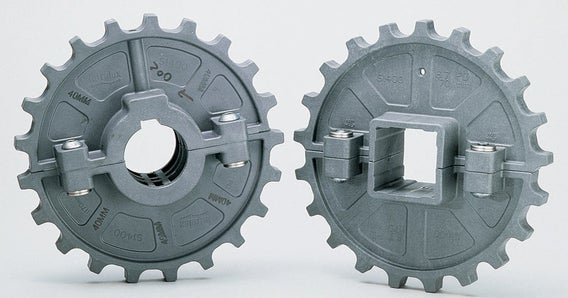

- Sprockets are all plastic.

- Most sprockets feature a split design, so shafts do not have to be removed for retrofits and changeovers.

- Robust design offers excellent belt and sprocket durability, especially in tough, material-handling applications.

- When using this belt on a center-drive conveyor, it can be necessary to retain the belt laterally, by placing collars at the backbend roller before the drive.

- Temperature, environmental conditions, and product characteristics affect the maximum degree of incline. Consider these factors when designing conveyor systems using these belts.

- Rubber indent: 1.0 in (25.4 mm).

| Base Belt Material | Base/Friction Top | Default Rod Material, Diameter 0.24 in (6.1 mm) | Belt Strength | Temperature Range (continuous) | Belt Mass | Friction Top Hardness | Agency Acceptability | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| lbf/ft | N/m | °F | °C | lb/ft² | kg/m² | FDA (USA) | EU MC1 | ||||

| Polypropylene | Grey/black | Nylon | 1,800 | 26,300 | 34 to 150 | 1 to 66 | 2.29 | 11.18 | 55 Shore A | 2 | |

European Migration Certificate providing approval for food contact according to EU Regulation 10/2011.

FDA compliant with restriction: Do not use in direct contact with fatty foods.