ONEPIECE™ Live Transfer Flat Top

Series 1400| in | mm | |

| Pitch | 1.00 | 25.4 |

| Molded Width | 6 | 152 |

| Width Increments | - | - |

| Open Area | 0% | |

| Hinge Style | Closed | |

| Rod Retention; Rod Type | Slidelox; unheaded | |

- Contact Intralox for precise belt measurements and stock status before designing equipment or ordering a belt.

- Smooth, flat surface with fully flush edges.

- Transfer edge is an integral part of the belt.

- Molded with robust tracking tabs to support the belt in heavy side-loading applications

- Nylon rods provide superior wear resistance.

- Slidelox are available in polypropylene or acetal.

- Each belt material has a default rod material. Other rod materials are available. Intralox can help identify the best belt and rod material combination for your application.

- Detailed material information is provided in Product Line.

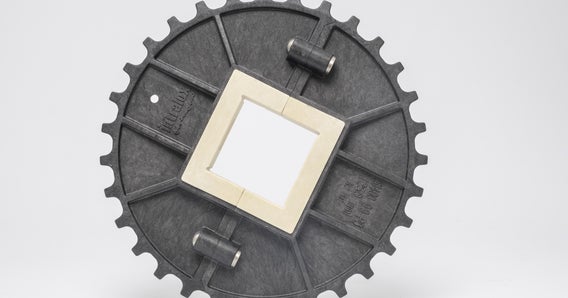

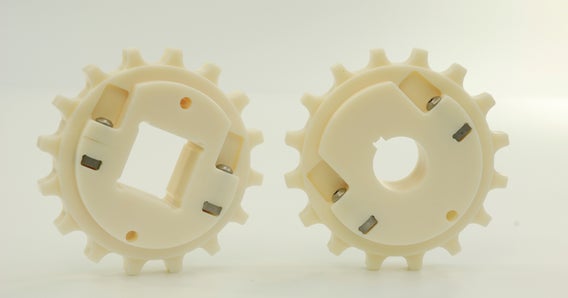

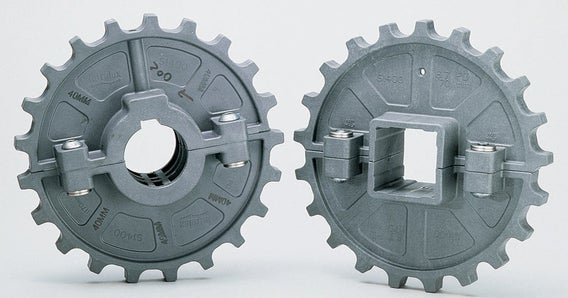

- Sprockets are all plastic, with large lug teeth for excellent durability and wear life.

- Most sprockets use the split design, so shafts do not have to be removed for retrofits and changeovers.

- Designed for smooth, self-clearing, right angle transfers onto takeaway belts.

- Provides excellent lateral movement of PET, glass, and other containers. Provides excellent belt and sprocket durability, especially in tough, glass applications.

- Addition of a fixed frame support can be necessary. The support ensures that the transfer belt does not snag when it intersects with the takeaway belt. Add support below the transfer belt, before the transfer. See 90-Degree Container Transfers.

- When moving products from transfer belt to takeaway belt, ensure the transfer belt surface is no more than 0.06 in (1.5 mm) above the takeaway belt surface. When product is moving from the infeed belt onto the transfer belt, ensure the belts surfaces are level.

- Available in 10 ft (3 m) increments.

| Belt Material | Default Rod Material, Diameter 0.24 in (6.1 mm) | Belt Strength | Temperature Range (continuous) | Belt Mass | |||

|---|---|---|---|---|---|---|---|

| lbf | N | °F | °C | lb/ft | kg/m | ||

| Acetal | Nylon | 850 | 3,780 | -50 to 200 | -46 to 93 | 1.25 | 1.86 |

| Document Name | Document Type | File Type | File Size |

|---|---|---|---|

| S1400_LiveTransferFlatTop_6inch_(Imperial).dxf | CAD Drawing | DXF | 1 MB |

| S1400_LiveTransferFlatTop_6inch_(Metric).dxf | CAD Drawing | DXF | 1 MB |