Baucells Reduces Water Consumption by 25% with SeamFree Belts

Case StudyBaucells

Products

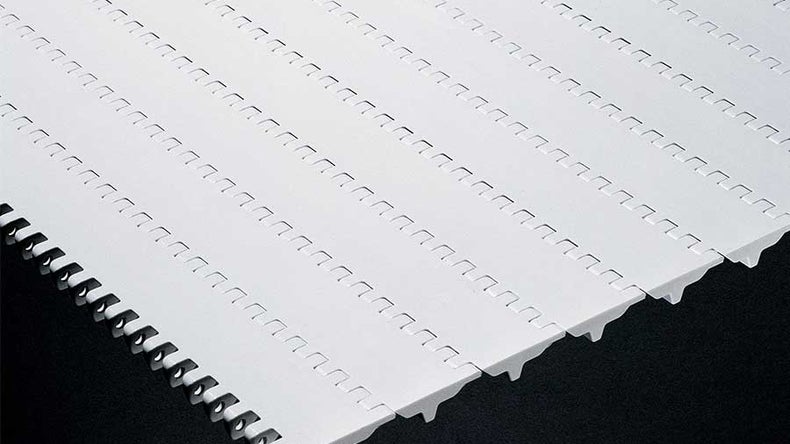

Modular Plastic Belting

Industries

Meat and Poultry

Grupo Baucells Alimentació, S.A., processes approximately 2800 hogs—or 220 tons (199,581 kg) of pork—per day. Belt cleaning procedures the company used in its cutting area were proving inefficient. Its conveyor belts’ design required that belts be cleaned twice per day to achieve desired appearance and bacteriological results. Baucells tried mixing water with pressurized air to increase water pressure, which enhanced cleaning efficiency without increasing water consumption. The additional costs, however, could not be justified.

To find a complete solution to their sanitation problems, Baucells contacted Intralox. The Intralox sales engineering team recommended Intralox SeamFree belting. Molded from nonporous, nonabsorbent plastic, SeamFree belts can be assembled without bricklayed seams up to a width of 36 in (91.44 cm). The widest plastic modules available on the market, SeamFree modules minimize debris-trapping areas to ensure better hygienic performance.

After implementing the Intralox solution, Baucells reduced water consumption by 25%. The belts now arrive at the desired hygiene level with just one cleaning, reducing time spent on sanitation. The SeamFree belt’s unique design makes it possible to access the previously inaccessible areas most susceptible to accumulating processing debris.