Tight Transfer Belt Enables Multi-SKU Production and Expansion for Seamless Empty Can Handling

Case StudyLeading Beverage Bottler

Products

Modular Plastic Belting

Industries

Beverages, Canmaking

Customer Objectives

A leading American beverage bottler needed to modernize their empty can–conveyance system to accommodate taller, sleeker 12-oz and 7.5-oz cans on their product lines. Their existing solution—a 35-year-old, ceiling-hung cable track conveyor system—posed significant operational challenges and made SKU changeovers nearly impossible.

In addition to limiting the bottler’s adaptability and innovation, the legacy system required dangerous, lift-assisted maintenance that put employees at risk. They needed a solution that could safely handle a growing variety of can sizes and formats while ensuring minimal downtime, less risk, and greater operational agility and efficiency.

Intralox Execution

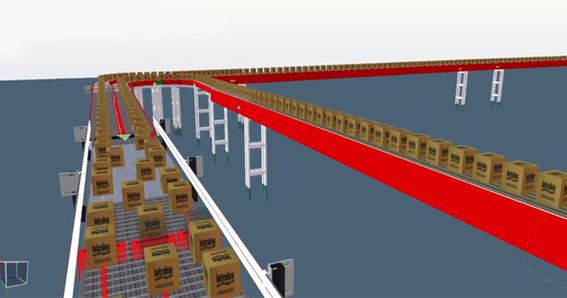

Because retrofitting the ceiling-hung system wasn’t possible, the bottler needed a completely new empty can–conveyance system that could support flexibility and growth. Intralox partnered with Sentry (a ProMach company) to design and install a ground-based, empty can–handling system using our Series 560 Tight Transfer belting. Alternative belting options required dead plates where empty cans can get stuck or stall; when switching between products, these stranded cans risk being filled with the wrong beverage. Intralox S560 belting enables belt-to-belt transfers that eliminate dead plates, preventing cans from getting stuck and removing the risk of product mixing or mislabeling.

Results

Our empty can–handling solution has met or exceeded all of the bottler’s expectations. The new conveyance system now handles multiple SKUs without risking downtime, product errors, or safety concerns, and supports production expansion and future packaging changes. It hasn’t required any maintenance in the 3 years since installation, and the S560 belt is expected to last more than 10 years, offering both longevity and reliability.

Since this installation, Intralox developed the S570 Tight Transfer belt. We improved sprocket engagement and rod retention to create a stronger, longer-lasting belt that’s easier to use. Even though their S560 belt has a lot of life remaining, the bottler plans to upgrade their empty can–conveyance system to S570 belting.

See this installation in action on YouTube.