Intralox’s Next-Day, Expedited Service Resumes Major Beverage Plant’s Production Just Days After Failure

Case StudyBeverage Bottling Plant

Products

Modular Plastic Belting

Industries

Beverages

Customer Objectives

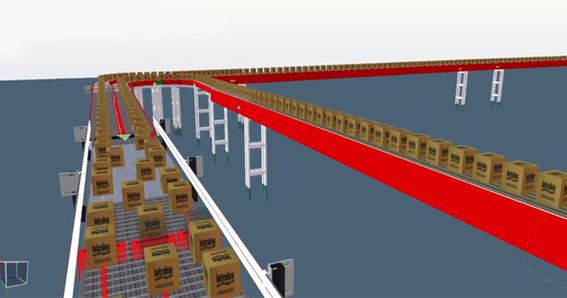

At a major U.S. beverage plant, the cooling tunnel belt on their hot-fill line had been running for seven years when it spontaneously failed late one Friday evening. The broken belt—which is 14-ft wide x 100-ft long (4.27-m wide x 30.48-m long) and processes 400–600 12-oz PET bottles per minute—brought production to a halt. When the plant called the belt manufacturer about a replacement, they were told to expect a 4-week lead time for expedited service.

Intralox Execution

The manufacturer was determined to resume production as quickly as possible. They called Intralox at 4:00 a.m. on Saturday. Our Technical Support Group immediately gave the plant retrofit guidelines and engineering advice for our Series 400 Raised Rib belt in Enduralox™ material. The Intralox belt was delivered the very next day. With their experience and skill, the facility’s maintenance team promptly modified the existing cooling tunnel infeed and outfeed to integrate the Intralox belt as quickly as possible.

Results

The facility was back to production by Thursday—less than a week after the initial belt failure. This limited downtime to just 11 shifts, compared to the 56 shifts of unscheduled downtime they might’ve faced had they waited for a replacement of their old belt.