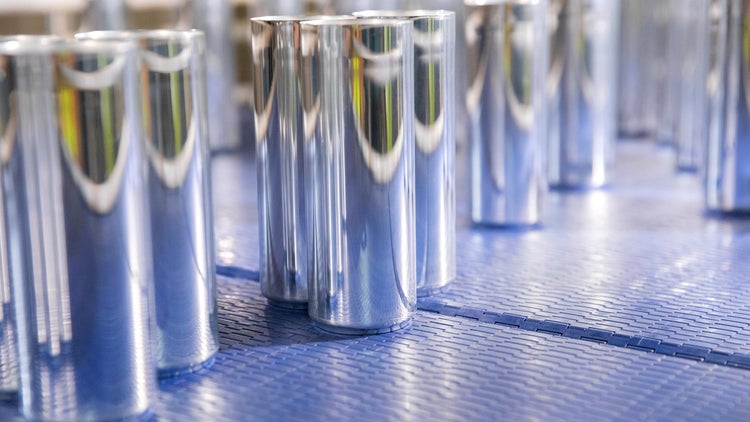

Eliminate Dead Plates and Reduce Spoilage on Canmaking Lines

Tight-transfer belting solutions for mass conveyance of empty cans help reduce the risk of mixed-label pallets and tipped cans

- Spotlight

- August 28, 2023

Erin Oakes, Intralox Business Development Engineer for the Canmaking Industry, explains how our tight-transfer nosebar solution ensures tip-free can transfers with no dead plates.

Intralox now offers exceptional tight-transfer modular plastic belting solutions for the canmaking industry. Eliminating the need for dead plate transfers, these tight-transfer solutions for mass can conveyance have been shown in field testing to reduce spoilage of empty cans by 70% compared to transfers with dead plates. This dead-plate-free belting system also prevents cans from becoming stranded on dead plates, reducing the risk of palletizing mixed labels and eliminating labor needed to clear the line of stranded cans at each label change.

Tight-transfer Intralox belts for canmakers and metal packagers currently available:

- Series 560 Tight Transfer Flat Top in blue acetal

- Series 570 Tight Transfer Flat Top in blue acetal

Benefits

- Reduce tipped cans and spoilage

- Eliminate stranded cans on dead plates

- Reduce risk of palletizing mixed labels

- Eliminate time-consuming and difficult dead plate maintenance on hard-to-access conveyors

Tip-Free Can Transfers Without Dead Plates

For can manufacturers seeking to eliminate dead plates and reduce product stranding, Intralox's tight transfer nosebars—available in 12-in (305-mm) increments—allow for the smallest possible transfer gaps. But with no dead plate to compensate for misaligned or incorrectly sized nosebars, the key to optimizing these transfers lies in their precise setup.

That’s why our nosebar transfer units are pre-assembled to ensure the exact alignment, levelness, and spacing required for optimal end-to-end transfers. Available in widths of 24 in, 36 in, and 48 in (610 mm, 914 mm, and 1,219 mm), the units include 6-mm-diameter blue nylon nosebars for small transfer gaps and optimal wear resistance, along with aluminum end caps and mounting plates. This brings your operation tip-free empty can transfers with minimal engineering and installation time.

Benefits

Nosebar

- 6-mm diameter ensures smallest possible transfer gaps

- Blue nylon material offers optimal wear resistance compared to metal or UHMW materials

Nosebar Transfer Unit

- Pre-engineered spacing, alignment, and waterfall remove guesswork

- Pre-assembly accelerates installation and eliminates post-installation adjustments