Conveyor belts for can manufacturing

Intralox brings maximum value to can manufacturers by continuously enhancing products and services customized to meet industry needs. Our extensive history and partnerships in the industry—and our position as the market leader—ensure we deliver proven and innovative technologies.

Our industry-specialized experts positioned around the world provide comprehensive, global support to any plant, no matter the location. By conducting plant surveys and focusing on can manufacturer priorities, we can offer the most valuable recommendations, services, and support for optimizing can plant efficiency.

Canmaking applications

Where can Intralox make the difference for you?

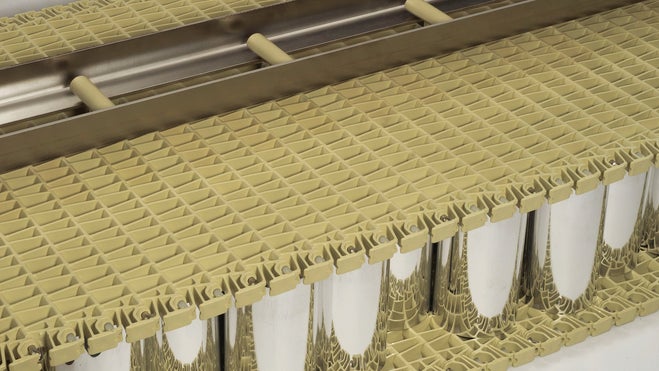

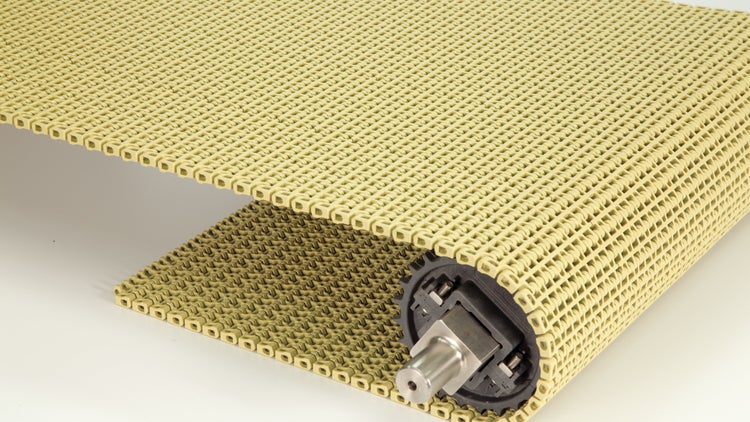

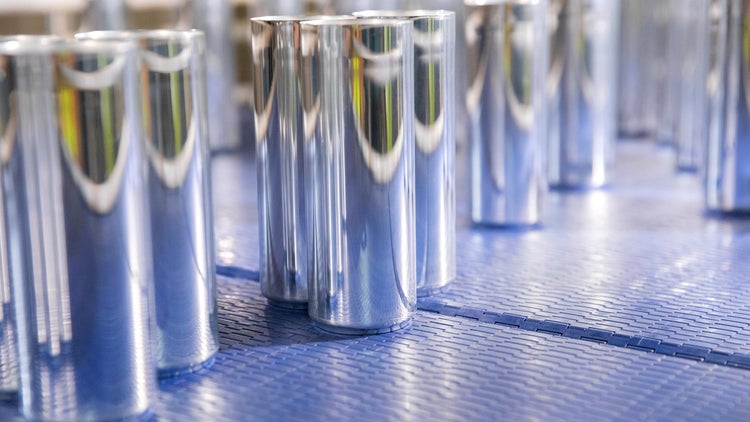

Mass HandlingEliminate dead plates and reduce spoilage with Intralox tight transfer solutions

Intralox's tight transfer belts provide exceptional solutions for mass can conveyance. Eliminating the need for dead plate transfers, these belts have been shown in field testing to reduce spoilage of 12-oz sleek cans by 70% compared to transfers with dead plates. They also prevent cans from becoming stranded on dead plates, reducing the risk of palletizing mixed labels and eliminating labor needed to clear the line of stranded cans at each label change.

Benefits of Intralox tight transfer solutions for mass handling

- Reduce tipped cans and spoilage

- Eliminate stranded cans on dead plates

- Reduce risk of palletizing mixed labels

- Eliminate time consuming and difficult dead plate maintenance on hard-to-access conveyors

Tight-transfer Intralox belts for canmakers and metal packagers currently available

- Series 560 Tight Transfer Flat Top in blue acetal

- Series 570 Tight Transfer Flat Top in blue acetal

Learn more about our tight-transfer solutions for mass can conveyance

Producing Results

The S560 has made a tremendous impact on reducing downed cans and has been maintenance free since it was installed. We have no worries on tip overs even with sleek cans. Any line would benefit from S560.

Devin Riley

Maintenance Supervisor at Ardagh–Olive Branch, USA

Industry InsightsCanversations Podcast Highlights Spoilage Reduction Audits

In this episode, Intralox leaders discuss our new spoilage reduction audits and how hands-on engineering support helps identify issues and apply solutions on the line.