Moving You Straight Ahead

Optimize A-to-B conveyance in every part of your plant

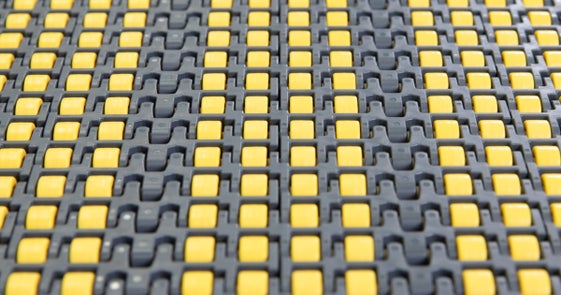

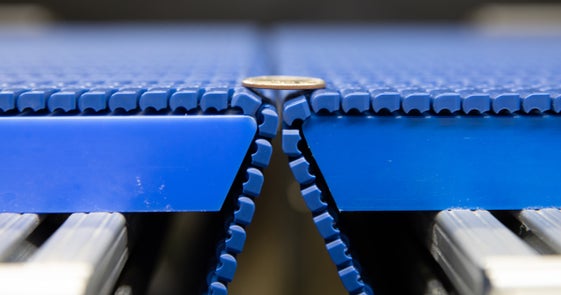

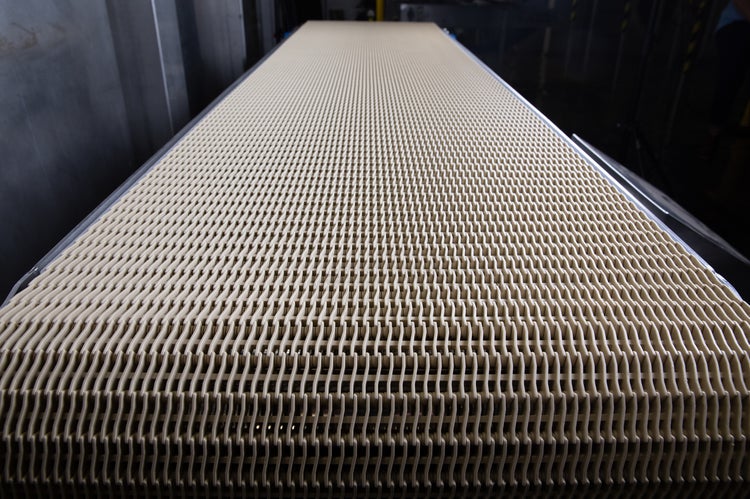

Straight-running Modular Belts

No matter the challenges of your application, we have a straight-running solution to help you overcome them.

Straight-running conveyor belts are foundational to the success of any manufacturer, processor, or distributor. If they perform as they’re supposed to, you may not even think about them. But if just one is not working correctly, it can cause problems across the whole line—possibly your entire plant.

Intralox straight-running modular plastic conveyor belts help you:

- Avoid increased or unexpected downtime due to belt breakdowns

- Simplify cleaning or maintenance procedures

- Eliminate product loss or contamination risks

With hundreds of options for series, style, material, accessories, and more, we have straight belts for almost any application. Our product experts ensure you get the right solution, backed by industry-leading guarantees.

Benefits

Intralox straight-running conveyor belts offer many key benefits, including:

- Longer belt life with less belt wear

- Simplified cleaning and maintenance

- Reduced risk of product loss or contamination

- Enhanced worker safety

- Zero need for lubrication or tensioning

Belt Options

What is your straight-running belt need?