Navigating the Building Blocks of Automation in Parcel Sortation

Automation isn’t all or nothing. Let’s find your in-between with the Bulk-to-Sorted product line.

- Insights

- July 7, 2025

When automating parcel sortation, the options can be overwhelming. With so many technologies, you’re not short on options—you’re short on knowing what's right for you.

You may be asking yourself:

- Should automation be designed to handle peak season or a regular day, flexing workforce as needed?

- How far into the future does my solution need to be designed for?

- Do I have the budget for upfront automation investment or am I optimizing around existing labor?

What if automation solutions were simple and could meet business needs today—while also being able to scale and perform as those needs evolve?

In this article, we’ll introduce a framework for understanding the stages of parcel sortation automation from fully manual to fully automated, and the steps in between. You’ll learn about the trade-offs and how to build a clear path forward based on your current needs and future goals.

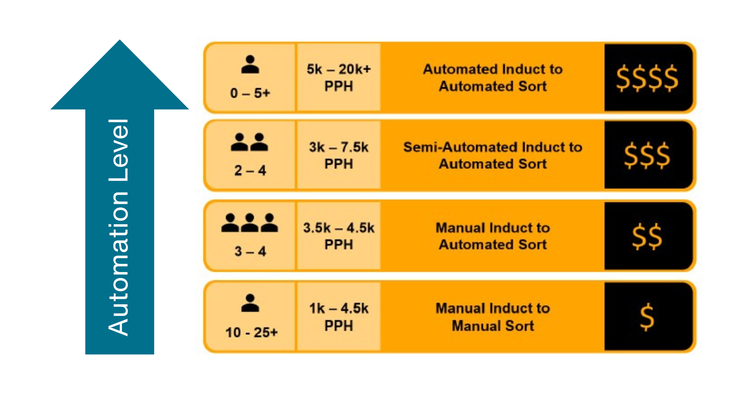

The Framework

The framework is defined by labor requirements, throughput rates (packages per hour), and CapEx investment level. As you move from fully manual to fully automated, operational expenses decrease while capital investment levels increase. Depending on your solution, rates may increase with automation but may be matched with less expensive semiautomated solutions.

Featuring our Bulk-to-Sorted product line, let’s break down each level.

Manual Induct to Manual Sort

For many businesses, this is probably the level you’re at.

At this stage, every package is handled by human hands. They’re carefully inducted and spaced out with labels facing up, so downstream operators can read them and manually sort them into their intended destinations.

This manually intensive operation demands high focus from each operator, so shift durations may need to be limited. In addition, with this setup, there’s a limit to how much throughput you can achieve unless you add a significant headcount—which is not practical for most operations.

Labor + Rate

- 10–25+ operators

- 1,000–4,500 pph

The First Step Forward: Automate Sortation

Introducing an automated sorter significantly reduces labor strain. Your team no longer manually sorts; instead, the few remaining operators needed feed the sorter.

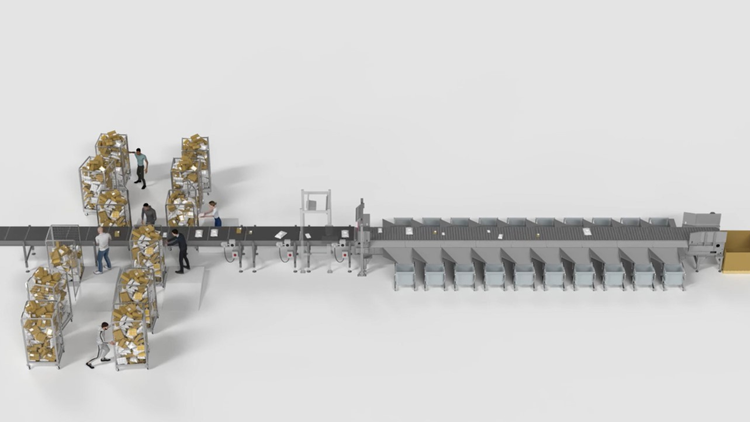

Manual Induct to Automated Sort

This level is where automation becomes a key part of the process for many operations. Though operators still manually induct each package, sorting is handled by the Activated Roller Belt (ARB) Sorter S7000 to greatly reduce headcount.

Labor + Rate

- 3–4 operators

- 3,500–4,500 pph (limited only by the induction operators)

What You Gain

- Significantly less sortation labor

Despite a lower headcount, induction is still manual. Challenges form at the start of the line as volumes grow and operators struggle to keep up. This leads to errors that reduce sorted throughput such as stacked packages, side-by-side packages, or insufficient gaps between packages.

That’s when teams start asking, "What if we could make feeding the sorter faster, easier, and more ergonomic?" or "How do we scale without doubling headcount again?"

Next Step Forward: Semiautomated Induction

To improve throughput, we need to relieve the growing pressure on operators who induct.

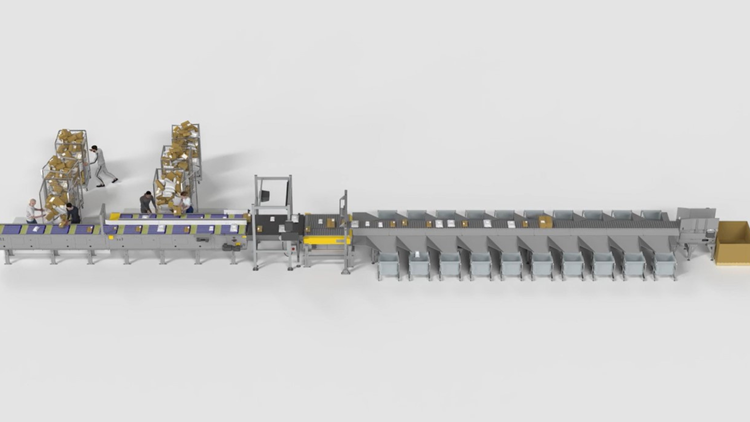

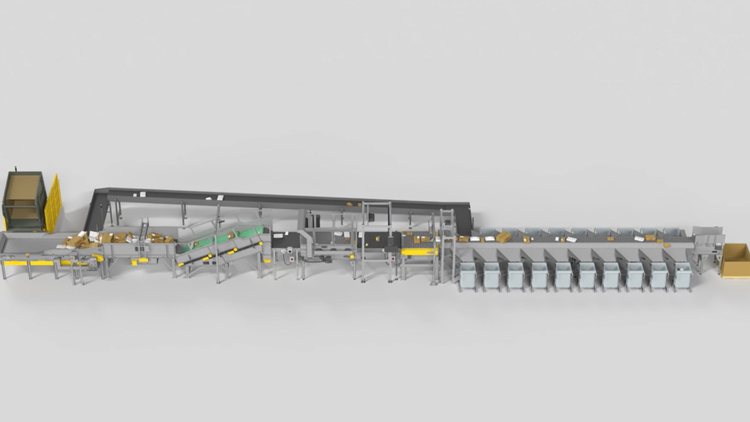

Semiautomated Induct to Automated Sort

At this stage, automation doesn’t replace your team entirely—it enhances them.

Semiautomation assists the operators, making the induction process more efficient. Operators no longer need to worry about precise package positioning; they simply place packages into pockets. From there, automation’s intelligence takes over by making a precise gap between each package for optimal sorter entry.

This layout relies on two key technologies from the Intralox Bulk-to-Sorted product line:

- ARB AutoPitch Induction: Mechanically creates the spacing between packages required by the downstream sorter

- ARB Sorter S7000: Precisely sorts packages to destination bins

Labor + Rate

- Approximately four operators

- Up to 8,000 pph

(Single-lane option available for rates up to 4,500 pph with three operators.)

What You Gain

- Up to 75% more throughput than fully manual induction

- Up to 50% less labor to achieve 8,000 pph

Next Step Forward: Full Automation

To eliminate labor entirely, you’ll need to automate the induction.

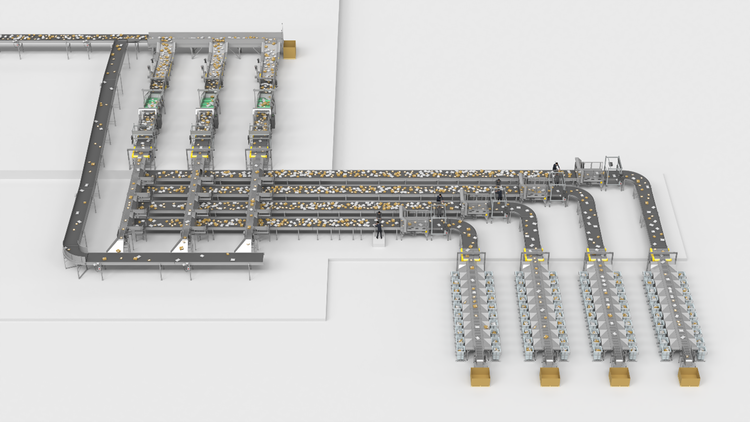

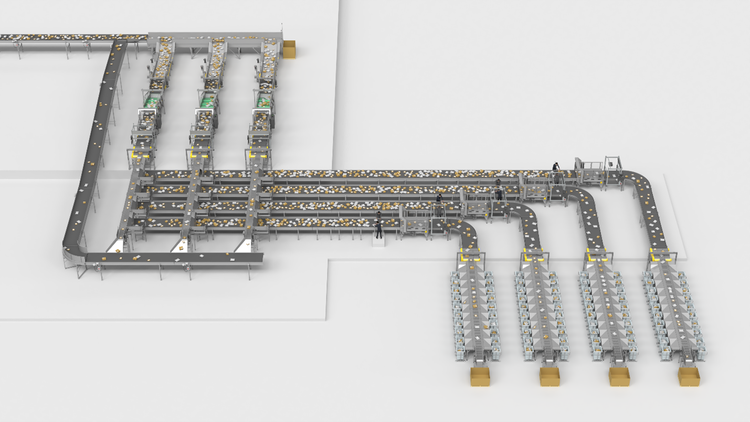

Automated Induct to Automated Sort

Here, you’re looking at a hands-free operation to induct packages to the sorter.

Packages often enter the system stacked and side by side from gaylord tippers, fluid truck unloading, or fulfillment bulk flow lines. This creates a messy, 3D package stream.

To clean that up, this system relies on three key technologies from the Intralox Bulk-to-Sorted product line:

- Bulk Flow Optimizer: Meters packages to lessen instantaneous throughput burst that cause overfeeding of the downstream singulator and sorter; also removes stacked packages

- SmartPath Singulator and Gapper: Eliminates side-by-side packages and provides the gap required for optimal downstream sortation

- ARB Sorter S7000: Precisely sorts packages to destination bins

Together, this equipment turns unpredictable flow into clean, consistent throughput.

Labor + Rate

- As few as zero operators

- Up to 7,500 pph

What You Gain

- Manual intervention kept at an absolute minimum

- 65% more throughput than manual induction

- Consistent rates across shifts

Next Step Forward: Future Proof Your Setup

As volumes grow and destinations multiply, you can continue scaling by adding primary and secondary sortation lines.

Simplicity Scales

Whether you’re just getting started or looking to level up, the key takeaway is this: Optimal performance doesn’t always require complex automation or a significant upfront CapEx budget. With the right framework, parcel sortation becomes a scalable journey—not an all-or-nothing leap. You can design for today while building a map for tomorrow, making decisions that balance labor, rate, investment, and automation in ways that work for you.

Every operation is different. That’s why our experts are here to help you weigh your options, understand trade-offs, and tailor a solution to fit your long-term goals.

Equipment SpotlightBulk-to-Sorted

The Bulk-to-Sorted product line keeps parcels moving. Its modular equipment distributes, singulates, gaps, and sorts for consistent flow and maximum throughput.