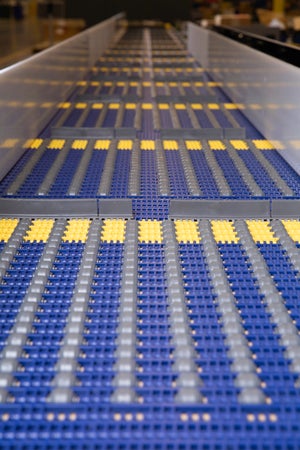

- ARB AutoPitch Induction

Simple, Low-cost, Semiautomated Induction

Get more done—no extra hands needed

Intralox’s ARB AutoPitch™ Induction is designed to tackle the biggest challenges in parcel sortation: complex automation systems, rising labor costs, and throughput inefficiencies.

This semiautomated solution automatically spaces manually inducted packages, freeing operators from focusing on precise package placement. The result? Faster induction, higher downstream sorter throughput, and fewer operators needed to achieve it.

Using ARB technology, AutoPitch Induction bridges the gap between fully automated and fully manual induction, delivering higher productivity without the high costs or complexities.

Optimized Throughput

- Sustained induction of 8,000 packages per hour at a fraction of full automation’s cost

- Improved induction productivity for higher sorter throughput

Lower Costs

- Less labor than fully manual induction

- Up to 65% lower upfront costs than fully automated solutions

Simple Mechanisms

- No specialized on-site maintenance required

- Comes integrator ready for fast, easy installation and commissioning

Equipment InsightsARB AutoPitch Induction

What sets this technology apart? Intralox Product Manager Jacqueline Sundstrand explains.

AutoPitch Induction makes induction a breeze for operators—just place the package in the pocket, and this solution takes care of the rest.

Jacqueline Sundstrand

Product Manager at Intralox