Schulze & Burch Finds Success—and Reinvests—in Intralox DirectDrive Systems

Case StudySchulze & Burch

Products

Spirals

Industries

Bakery

Customer Objectives

A friction-driven spiral used to cool toasted pastry products was inhibiting operations at the Schulze & Burch facility in Searcy, Arkansas. Excessive inside belt edge movement disrupted product alignment and increased tension, causing belt modules to snap. Each time it happened, product had to be scrapped due to risk of foreign material contamination and production stopped for repairs and cleaning. Schulze & Burch sustained losses in the hundreds of thousands of dollars due to lost product and unscheduled downtime costs whenever the belt snapped. And it happened regularly.

Plant officials increased sanitation efforts, added preventive maintenance inspections, installed multiple belt sensors, lubricated wearstrips, and invested $500,000 in aligning equipment. Nothing worked. The friction-driven spiral remained the facility’s most troublesome conveyor. Schulze & Burch needed to replace it with new technology that would run consistently, remove product contamination risks, and eliminate unscheduled downtime.

Intralox Execution

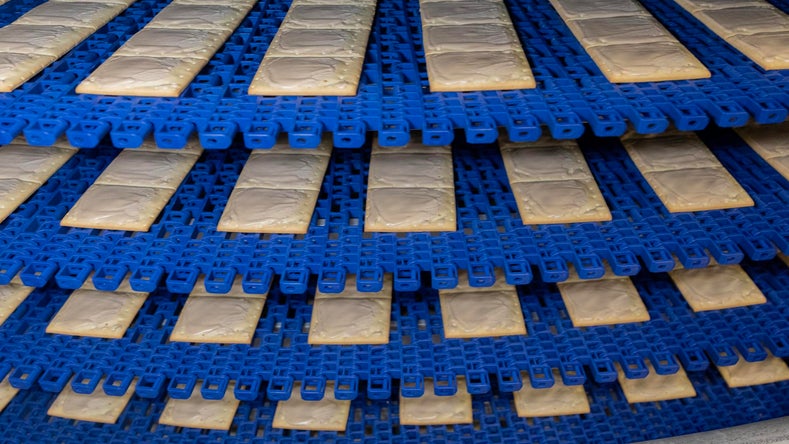

While attending PACK EXPO in 2013, several Schulze & Burch employees came across the Intralox exhibit. Impressed by the spirals on display, they inquired about a solution to replace their problematic friction-driven spiral cooler. Intralox recommended its patented, low-tension DirectDrive System (DDS) and arranged for Schulze & Burch staff to see it in action at another facility. Convinced they found the perfect solution, plant officials purchased a DirectDrive spiral cooler and had it up and running the following spring.

Schulze & Burch also opted to include IntraloxIntelligence, a patented innovation for remote spiral monitoring that continuously measures data which is used to maintain optimal system performance.

Results

Since installing the DirectDrive spiral in 2014, operations at the Schulze & Burch Searcy plant have improved dramatically. The belt hasn’t broken, and the spiral has caused no unscheduled downtime, product contamination, scrapped product, or held orders. Product alignment is excellent, and the original belt is still running reliably. In addition, the IntraloxIntelligence sensor node continues to transmit data, which is analyzed by Intralox experts who make recommendations to further optimize the system’s performance.

“It’s been a complete transformation,” says Alan Freeland, Schulze & Burch General Manager. The Intralox solution converted the spiral cooler from the worst performing equipment to the best performing equipment at the Searcy facility, allowing efforts to be redirected to other key challenges. Each year, on the anniversary of its installation, plant officials hold a celebration for the employees to mark the success of their DirectDrive spiral cooler.

Based on the exceptional performance of the DirectDrive System, Schulze & Burch purchased and installed a second DDS structure-supported spiral for its facility in Chicago, Illinois. That system has also performed well, improving cooling capacity, production efficiency, sanitation needs, and uptime.

Our operation in Chicago needed additional cooling capacity for the toaster pastry line. Based on the performance of the DirectDrive System at our Searcy plant, the decision was simple. We purchased and installed our own DirectDrive spiral and it's been running exceptionally well.

Steve Egizio

Schulze & Burch Biscuit Company Director of Technical Services