Greenfield Brewery Transforms Back-end Layout Efficiency

Case StudyGlobal Brewer

Products

Modular Plastic Belting, ARB Equipment

Industries

Beverages

Solutions

Layout Optimization

Customer Objectives

In 2024, a global brewer invested in a new beer plant to meet evolving market demands and expand their influence in southern China. The greenfield project included two 48,000-bottles-per-hour (bph) lines and one 90,000-cans-per-hour (cph) line in the back end of the plant. The new lines needed to meet the following criteria:

- Overall line efficiency > 95%

- Increase accumulation in a small footprint

- Gentle handling to protect products and ensure quality

- Convey different packaging types on the same line with quick product changeovers

- Allow for future line upgrades, including sustainable packaging changes

The global brewer had successfully collaborated with Intralox in several breweries in China and in Europe via their OEMs. They recognized the value of our products and services. The system integrator chosen by the global brewer contacted Intralox early in the project to consult on layout solutions.

Intralox Execution

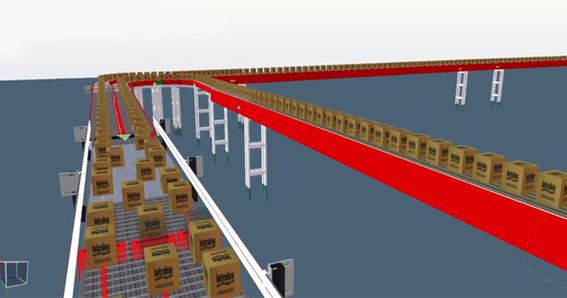

Working closely with the brewer's onsite team and local integrator, Intralox engineers provided 2D AutoCAD drawings and 3D simulations showcasing new layout options. Recommendations focused on full-capacity operation, accumulation capabilities, eliminating dead plates for gentler handling, and overall line efficiency. Simulations of potential real-world production issues helped the team assess risks and deliver the final solution.

Highlights:

- Layout optimization options provided at pre-sales stage

- Regular meetings with stakeholders

- Design review and on-site check with OEM post-build

- Expedited belting delivery

The layout optimization consulting provided by Intralox is truly impressive, offering a clear visualization that has helped us to avoid potential issues effectively. Moreover, Intralox's conveyor belts and ARB equipment have proven to be highly reliable in our packaging line. Coupled with their comprehensive lifecycle management services, our project has progressed exceptionally smoothly.

Project Manager

Global Brewer

Results

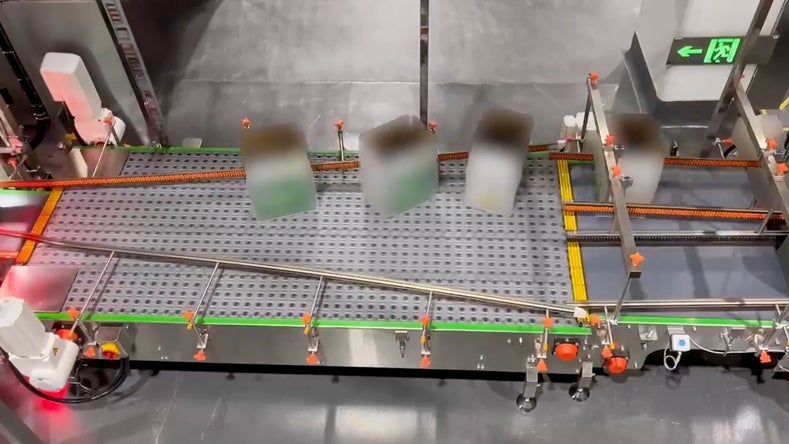

With Intralox layout optimization, belting, and Activated Roller Belt™ (ARB™) equipment as a total solution, the entire back-end packaging line became more efficient. The small footprint created over 3.2 ft (1 m) of extra space for workers and equipment.

The new lines balanced input and output, eliminating the need for frequent starts and stops of core equipment. This efficiency also delivers long-term energy savings for the brewery.

By eliminating dead plates and implementing tight transfer solutions, accumulation capacity was increased, and the brewer's delicate products are conveyed without damage. The can line and bottle lines can easily be adapted for future product needs.

* The S7050 vs. comparable technologies