Spiral Optimization Solves Debris and Maintenance Problems for Beretta

Case StudyBeretta

Products

Spirals

Industries

Meat and Poultry

Customer Objectives

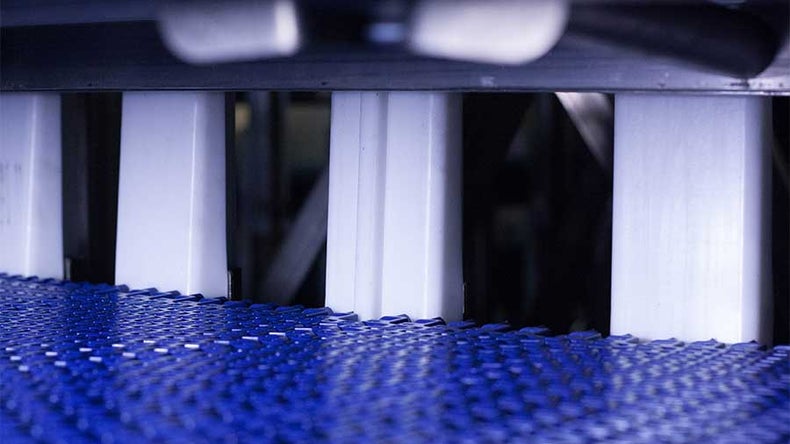

Salumificio Fratelli Beretta was having trouble with its metal spiral conveyor used for drying salumi at its Garbagnate Monastero, Italy, plant. Most problems came from metal wear debris, though the conveyor also experienced excessive belt tension, creating a short belt life. The tension and debris necessitated frequent maintenance to and replacements of carryway wearstrips and cagebar caps.

Intralox Execution

Beretta has Intralox belting in other plants and applications, so it was familiar with the company’s quality products, service, and performance guarantees. Intralox managed the complete retrofit, from the in-house evaluation with special instruments to the conveyor’s eventual startup. This Spiral Optimization package provided Beretta with a guarantee on all belts, components, and labor to ensure satisfaction.

Intralox gave Beretta samples of DirectDrive Series 2700 and 2800 belting free of charge to run tests. The plant was able to compare the two available belt series and analyze the effect of modular plastic belting on their drying spiral through production and quality control.

Results

Beretta chose the DirectDrive S2800 belt because of its greater uniform open area for cooling and increased airflow. Since its installation in late 2012, Intralox belting has proven a success in the Garbagnate Monastero plant, eliminating the metal wear debris risk. Beretta’s salumi has reached the same humidity degree as it did with the previous solution.

Intralox recommended drum power and gear reductions, which led to additional benefits for Beretta. Cleaning time has decreased by 30%, and dwell time has been reduced from 60+ minutes to 50–60 minutes with no flip-up risk. Belt tension is at virtually zero.