Reduce maintenance and replacement costs with the longest-lasting washer belt in the canmaking industry.

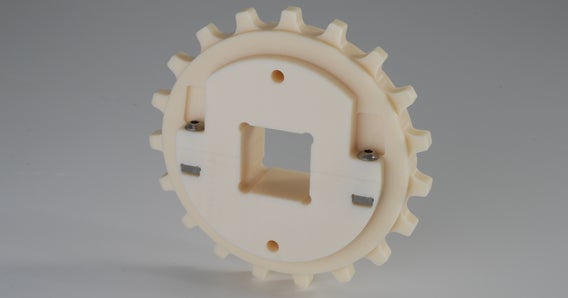

Built specifically for can washing applications, Intralox Series 9000 Flush Grid belting provides reliable operation without sacrificing strength or performance. The belt’s innovative modular plastic design ensures easy maintenance, and its lack of sharp edges maximizes worker safety.

- Modular design guarantees a level conveying surface

- Chemical-resistant material promotes belt longevity

- Enhanced open area supports thorough can cleaning

| in | mm | |

| Pitch | 1.00 | 25.4 |

| Minimum Width | 6 | 152.4 |

| Width Increments | 1.00 | 25.4 |

| Opening Size (approximate) | 0.7 x 0.5 | 17.8 x 12.7 |

| Open Area | 58% | |

| Hinge Style | Closed | |

| Rod Retention; Rod Type | Occluded edge; unheaded | |

- Contact Intralox for precise belt measurements and stock status before designing equipment or ordering a belt.

- Open surface enhances spray-through cleaning performance and airflow cooling performance, depending on the application.

- PVDF is a polymer material proven for long-term use in washer environments.

- Each belt material has a default rod material. Other rod materials are available. Intralox can help identify the best belt and rod material combination for your application.

- Detailed material information is provided in Product Line.

- Available with split steel sprockets for longer sprocket life and easier replacement.

- Easy to retrofit from existing steel belting with virtually no conveyor changes.

| Belt Material | Default Rod Material, Diameter 0.18 in (4.6 mm) | Belt Strength | Temperature Range (continuous) | Belt Mass | |||

|---|---|---|---|---|---|---|---|

| lbf/ft | N/m | °F | °C | lb/ft² | kg/m² | ||

| PVDF | PVDF | 1,000 | 14,600 | 34 to 200 | 1 to 93 | 1.57 | 7.64 |

| Polypropylene | Polypropylene | 750 | 10,900 | 34 to 220 | 1 to 104 | 0.82 | 4.00 |

| Acetal | Polypropylene | 900 | 13,100 | 34 to 200 | 1 to 93 | 1.14 | 5.57 |

| Document Name | Document Type | File Type | File Size |

|---|---|---|---|

| Series 9000 Can Washer Hold Down Mat Product Highlight | 448 KB | ||

| Series 9000 for Can Washers Application Highlight | 1 MB |