Conveyor Belt Tools and Joining Methods

Reliable Intralox solutions for fast, safe, and hygienic conveyor belt joining, installation, and upkeep

- Spotlight

- December 23, 2025

Intralox provides reliable, easy-to-use solutions for conveyor belt joining, installation, and maintenance.

Our innovative tools and joining methods are designed to minimize downtime, improve safety, and extend belt life. Whether you need the fast, splice-free connectivity of ZeroSplice technology or specialized tools for belt handling and maintenance, we have proven options to keep your operation running at peak performance.

ThermoDrive Belting

ZeroSplice Technology

The reliable alternative to splicing, Intralox ZeroSplice technology enables food processors to connect ThermoDrive belts quickly and easily without field splicing. It uses our reliable, fully enclosed lace connections to install belts in minutes with no added cost—delivering faster, easier, do-it-yourself installation.

ThermoDrive Splicing System

When splicing is required, the ThermoDrive Splicing System makes permanent, hygienic splices in ThermoDrive belting. It delivers accurate, square joints that won’t cause mistracking and can be used on either the carryway or returnway for flexible installation.

More forgiving than traditional vulcanizing methods, this System doesn’t require complex finger joints or specialized presses. It helps extend your belts’ life with repairs instead of replacements.

Compatible with all Intralox ThermoDrive belts

Modular Plastic Belting

Rods

Intralox belt rods connect interlocked belt modules, providing flexibility and reliable movement. They allow sections to be installed, replaced, or repaired individually without requiring a full belt replacement.

Rod design and material vary by belt series to support specific application needs. The right combination ensures smooth operation, proper alignment, and optimal wear resistance in any environment.

OneTrack Tools and Components

Clean Release

Intuitive and tool-free, the Intralox Clean Release system facilitates removal and installation of Intralox S800 Heavy-Duty Edge belts. Featuring stainless steel construction, it helps eliminate belt edge and rod damage, thus minimizing foreign material risk.

Compatible with Intralox S800 Heavy-Duty Edge belt

Belt Pullers

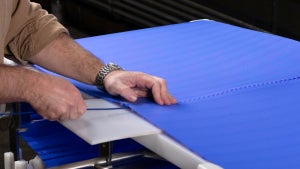

Intralox Belt Pullers simplify conveyor belt handling to ensure faster, safer installation and maintenance. Built from solid metal, these ergonomic solutions enable a smaller number of workers to install or remove large sections of belting by providing safe ways to pull belts onto a conveyor.

Belt pullers can be used in either the carryway or returnway to reduce the risk of injury or belt damage. They also allow you to secure the belt in an open position on the conveyor frame for easier access during cleaning and maintenance.

Rod Remover

The Intralox Rod Remover reduces the risk of damage to belt edges or rods—as well as related foreign material risks—during rod insertion or removal. Usable in either the carryway or returnway, it ensures quicker rod removal and less downtime during maintenance and sanitation.