All for One. OneTrack for All.

Tools and Components Direct from Intralox

- Spotlight

- October 20, 2025

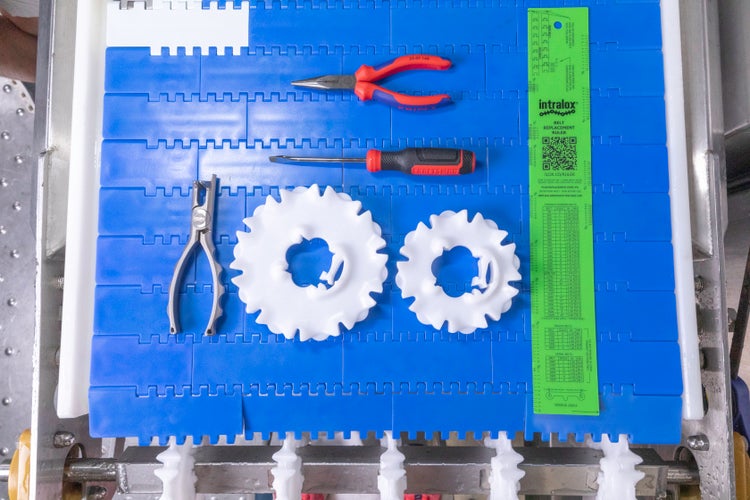

Simplify sourcing and accelerate installation and maintenance with Intralox’s OneTrack™ suite of tools and components, bringing together everything our partners need to optimize their conveyors’ performance.

Sourced directly from Intralox, this comprehensive portfolio of belt path components, maintenance tools, and more is backed by our industry-best guarantees and lead times. Plus, for our food partners, each OneTrack component or tool available within The Intralox® FoodSafe™ System has been approved by hygienic design–certified engineers at Commercial Food Sanitation (CFS).

Benefits

- Simplify projects and orders with one unified source for all conveyor needs

- Optimize belt installation and repairs with easy-to-use maintenance tools

- Compatible with both ThermoDrive and modular plastic belting conveyors

- Reliably stocked and available with industry-best lead times

- Backed by Intralox’s expertise, services, and guarantees

Features

OneTrack products for The Intralox FoodSafe System include:

Belt Path Components

- Rollers

- Wearstrips

- Sprockets

- Retainer rings

- Shafts

- Support wheels

- Limiters

- Scrapers

- Spacers

LugDrive S8140 belt with sprockets and support wheels

Tools for Maintenance and FMC Prevention

- Clean Release

- Belt Replacement Ruler

- Belt Puller

- Rod Remover

- Clean-in-Place Spray Bar

Intralox rod remover

Solution Spotlight

The Intralox Clean-in-Place System

Automated sanitation's effectiveness depends on both its technology and the procedures that support it. Our system enhances both, with solutions designed to maximize the cleanability of Intralox® FoodSafe™ belts and sprockets. The Intralox Clean-in-Place (CIP) spray bar enables simpler washdown with less cleaning time and water usage than manual cleaning. Combining it with education from CFS and Intralox experts reduces process waste, improves hygienic design, and optimizes sanitation effectiveness and efficiency.