Intralox ARB Switch S7000 Provides Reliability and Saves Total Cost of Ownership by 99%

Case StudyGrupo Petrópolis

Products

ARB Equipment

Industries

Beverages

Customer Objectives

Grupo Petrópolis is currently the second largest brewer in Brazil and the only 100% Brazilian large company of the segment. It owns the brands of beers Crystal, Lokal, Itaipava, Black Princess, Petra, and Weltenburger; energetic beverages TNT Energy Drink and Magneto; isotonic Ironage; vodkas Blue Spirit and Nordka; and Petra mineral water. With five factories in operation and one more under construction, Grupo Petrópolis is responsible for generation and maintenance of 19,000 direct jobs. In addition, the company sponsors professional and amateur athletes and promotes environmental actions through the AMA project.

The plant located in Boituva, São Paulo, is one of the strategic plants of Grupo Petrópolis. It manufactures a variety of beer products in multiple package types and sizes.

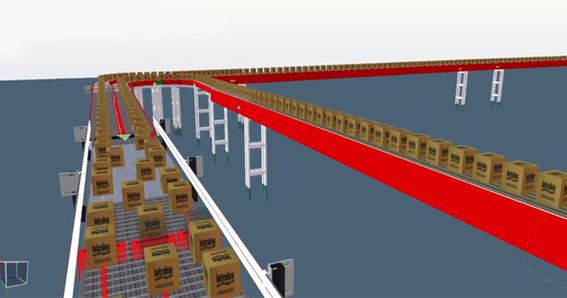

The Boituva plant used to have a slat switch installed at the palletizer infeed to balance the flow of one of the can lines. The slat switch had worked in the plant for eight years; however, due to its mechanism, the slat switch caused several issues:

- High maintenance – In order to keep the switch running, the plant had to spend two hours on weekly preventive maintenance to fix the slat switch’s problems.

- Frequent unscheduled downtime – The slat switch caused frequent unscheduled downtime regardless of the preventive maintenance. Due to the location of the slat switch on the production line, the entire line—including fillers and palletizers—had to be stopped when the slat switch was down.

- Costly part replacement – Maintenance and repairs required replacing failed parts, which were costly to the plant.

The switch became the bottleneck on the production line. Scheduled production time is valuable to the plant because it operates 24/7; therefore, unscheduled downtime is not acceptable. The Boituva plant sought a reliable solution to its problems.

Intralox Execution

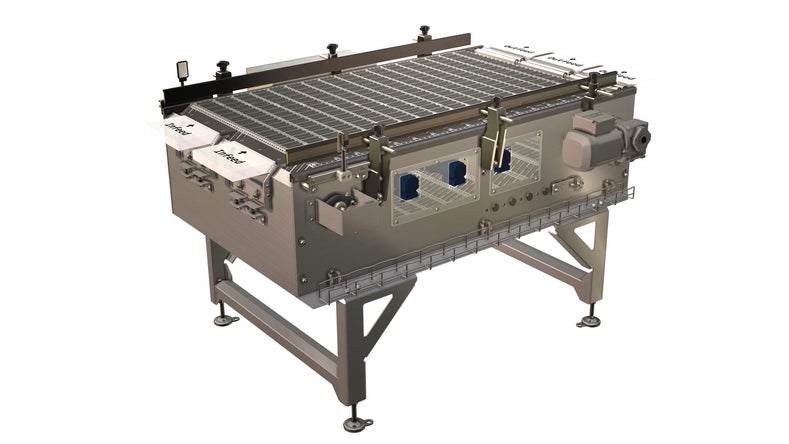

After evaluating different options, the plant selected the Intralox Activated Roller Belt (ARB) Switch S7000, which is designed for high-speed, reliable, and consistent functions to this application. As the ARB Switch S7000 could fit into the line perfectly without modifications, the unit was a drop-in installation. The ARB Switch S7000 was simply installed during the regularly scheduled, two-day preventive maintenance time.

Results

The ARB Switch S7000 has provided consistent, reliable performance since May 2012. The plant is happy to see:

- Lower maintenance costs – The cost of part replacement is reduced by about 92%.

- Easier maintenance – Maintenance operations are simplified. No part replacement is required any more; therefore, the plant saves labor resources for more valuable maintenance operations.

As a result of the success of the installations, the plant achieved payback of the investment on the equipment in six months with cost savings of 99%.