Grated Cheese Producer Improves Product Quality and Yield With Patented Intralox Technology

Case StudyGrated Cheese Producer

Products

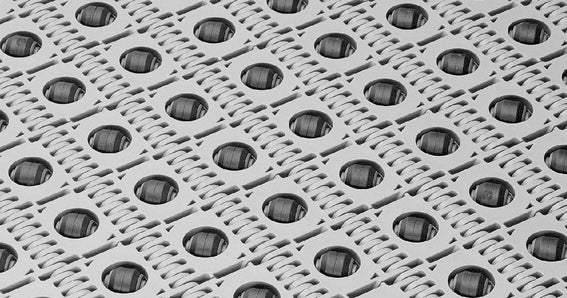

ThermoDrive Belting

Industries

Dairy

Customer Objectives

A grated cheese producer in New Zealand was experiencing product buildup on their belting. A common industry problem caused by grated cheese’s stickiness, buildup was decreasing product uniformity and yield, increasing sanitation downtime, and creating foreign material contamination (FMC) risks. Many producers accept buildup as an unavoidable industry challenge; this one approached Intralox looking to solve it.

Intralox Execution

Our experts recommended a combination of two patented technologies: ThermoDrive BarDrive Series 8050 belting and an Intralox Drive Unit (IDU) with scraper. The belting offers superior release for sticky products, and its hygienic properties simplify sanitation. Plus, the IDU’s unique design significantly reduces the risk of the belt slipping and jumping during operation. The drive’s reliable performance ensures the spring-loaded scraper maintains consistent pressure across the width of the belt while resisting wear. By combining our ThermoDrive technology with the IDU, the cheese producer could maximize the amount of product released from the belt, protecting their production stream from clumps or old product.

The scraper has kept the belt a lot cleaner. We don’t get the product buildup that we’ve seen in the past, making cleaning easier. We also don’t get the same amount of product clumps falling into the product stream.

Plant Maintenance Lead at Grated Cheese Producer

Results

As expected, the Intralox solution significantly reduced cheese buildup on the belt, improving production yield, profitability, and ease of sanitation while also decreasing FMC risk. Since installation, the plant has experienced no product quality issues and greatly reduced their time spent cleaning. After this installation’s success, the cheese producer purchased five additional IDU and scraper combinations for their ThermoDrive conveyors.