ARB Switch Enables Canélia to Launch New Pallet Format

Case StudyCanélia

Products

ARB Equipment

Industries

Beverages, Dairy

Canélia is a milk producer based in Petit-Fayt, France, and a member of the worldwide leader in dairy: Lactalis Group. At the Canélia bottling site, 1-L polyethylene bottles of milk are shrink-wrapped in groups of six, eight, or 10 at a throughput rate of 15,000 bottles per hour. The 8-L and 10-L packs were being fed to the palletizer at the line’s maximum throughput rate. To meet new demands, the dairy needed to create a new pallet format as well as revise the arrangement of the bottles on each pallet layer while maintaining throughput.

The dairy was using lateral adjustable guide rail conveyance technology to feed the palletizer via one line. To achieve the new pallet format, however, two lines were required. As guide rail technology required time-consuming adjustments to accommodate the different pack sizes, it was no longer a viable conveyance solution. Additionally, it was to blame for frequent jams and damage to the package shrink-wrap. This led Canélia dairy to consult with an integrator and Intralox for a better conveyance solution.

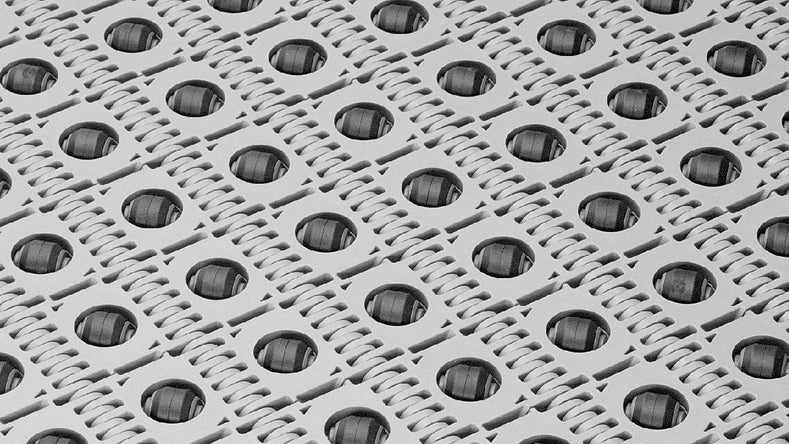

In a simulation, Intralox presented the Activated Roller Belt (ARB) Switch S400, an automated conveyance solution to feed the palletizer via two lines, requiring no adjustments for varying package types. Guard rails and the associated package damage have been eliminated. The Intralox switch has optimized production throughput and enabled Canélia to meet market demand for various pallet sizes and arrangements.

What’s remarkable about the ARB switch is its simplicity as it continually, smoothly moves the products. This solution responded perfectly to our needs.

Mr. Mathieu Agranier

Canélia Head of Production