Conveyance systems for fruit and vegetable processing

Our fruit and vegetable industry specialists are committed to helping you achieve your operations, sustainability, and food safety goals. For every type of product and any type of application—from receiving to secondary packaging, from direct food contact to case handling—we’ll work with you to determine the right solution.

We provide solutions across a range of fruit and vegetable segments, including:

- Fresh produce

- Frozen products

- Canned, jarred, and pouched products

Fruit and vegetable processing applications

Where can Intralox make the difference for you?

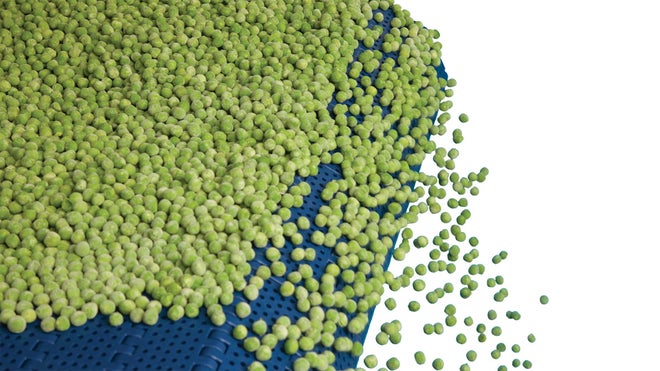

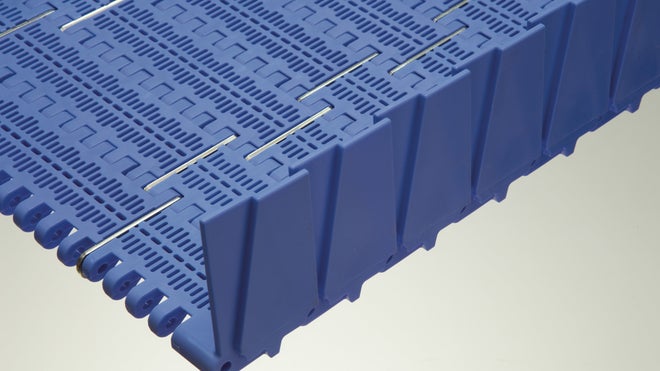

ReceivingTake abrasion resistance to a new level

In the harsh, highly abrasive conditions of the receiving area, debris and grit can migrate and accumulate between belt modules and rods, causing wear and shortened belt life. Series 1700 and 1750 Flush Grid belts are designed specifically to address high-abrasion challenges that can lead to shortened belt life, unscheduled downtime, low process reliability, and other issues common on receiving lines.

Benefits:

- Ideal for highly abrasive loads and long production cycles

- Designed for straight runs, inclines, and declines

- Engineered to reduce downtime and lengthen belt life

Download the Series 1750 and 1700 Flush Grid Product Highlight (PDF)

By the Numbers

Solution SpotlightReinvent Your Fresh Produce Processing from Packer to Palletizer

Consulting with Intralox at initial concept planning allows fresh produce processors to automate all or some of the back end of their plants.

Learn more about our Packer to Palletizer solutions for fresh produce

Insights and Results

Fruit and vegetable processors find success with Intralox solutions