When Less Is More

Chain belts deliver maximum performance at minimal widths

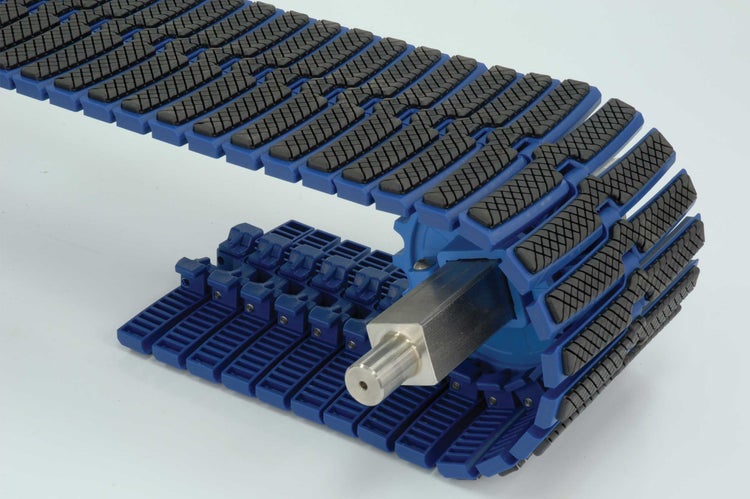

Modular plastic chain conveyor belts

You have many options for chain belting. Downtime isn't one of them.

Drop-in ready and available in standard widths, Intralox chain belts reduce wear on pans, containers, bottles, cartons, totes, crates, and more. Our options for shipping lead times (including next-day and four-hour), plus our industry-leading services and support, ensure you get the most from your chain, whenever you need it.

Benefits

Key benefits of Intralox modular plastic chain belting include:

- Simple to retrofit or drop-in replace onto your existing conveyors

- Lighter and easier to work with than metal belt alternatives

- Reduced noise due to lower friction of plastic components

- Robust designs ensure longer belt life with reduced breakage

- Proven energy savings of up to 19% compared to metal chain belts

Belt Options

What is your chain belt need?