ThermoLace Heavy-Duty Edge Belting

Upgrade your ThermoLace belts and leave splicing behind

- News

- February 23, 2023

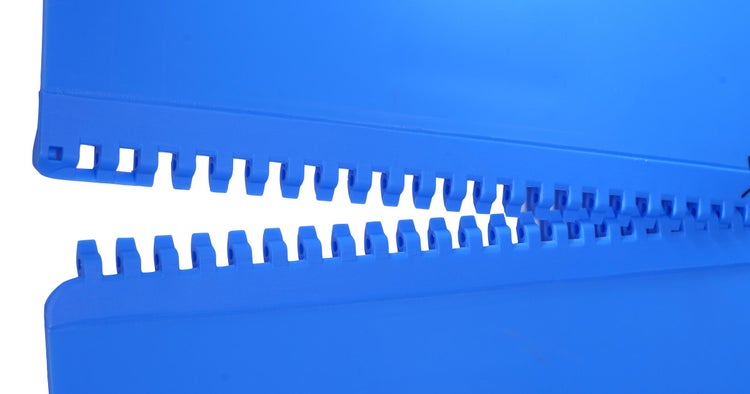

With the release of ThermoLace Heavy-Duty Edge (HDE) belting, food industry manufacturers can say goodbye to splicing headaches. The new ThermoLace HDE belt equips food processors with the hygienic benefits of a homogeneous thermoplastic material and the do-it-yourself nature of a hinge (like a modular belt) for use in light- to medium-duty applications.

ThermoLace HDE is compatible with our lug-driven Series 8140 belting and full-width drive bar Series 8050 belting. Contact Intralox Customer Service (available 24/7 in most regions) to learn more about available series, style, and material combinations.

Features and Benefits

- Alleviate splicing dependency: The ThermoLace HDE accessory enables faster, DIY belt installation and/or removal using readily available tools, making it easier to reduce unscheduled downtime.

- Heavy-Duty Edge design: Fully enclosed edge eliminates rod migration risk and ensuing catchpoint failures.

- Easy drop-in replacement for existing ThermoLace belts: Upgrading to ThermoLace HDE belting requires no changes to the conveyor frame and no price increase.

- Optimized ThermoLace accessory: The smaller-sized part allows for 90% less surface profile disruption and facilitates more accurate sprocket/roller wrap for a smoother running belt.

- Improved lace-to-belt reliability: New manufacturing process results in tougher lace-to-belt joints, driving longer belt life and reducing unscheduled downtime.

Material Availability

Our ThermoLace portfolio is available in a comprehensive range of hygienic lace materials developed to optimize performance from receiving to packaging. Each is ideal for specific environmental conditions and applications.

We recommend polyurethane (PU) for general food conveyance and for its abrasion resistance. In warm, damp conditions, our PU A23 material offers hydrolysis resistance and performs well in high temperatures.

ThermoLace HDE belting in Dura is a best-in-class solution for heavy-duty, high-impact conveyance where regular belt removal is required. It's resistant to peracetic acid and is ideal for subfreezing environments.