Simplify Dip Tank Belt Maintenance

The Intralox Tensioner for S1700 FG/FGNT belting makes repairs easier and safer

- Spotlight

- January 2, 2026

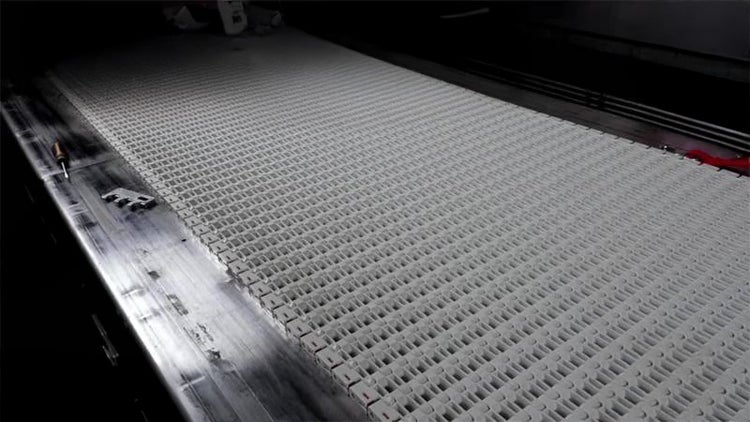

Make dip tank belt repairs easier and safer with one simple tool. The Intralox Tensioner for Series 1700 Flush Grid/Flush Grid Nub Top belting is custom designed for ease of use and reliability.

Servicing wide, heavy belts without the proper tools is a recipe for trouble. It can damage or break your belting, injure workers, and require 4–6 people for tensioning.

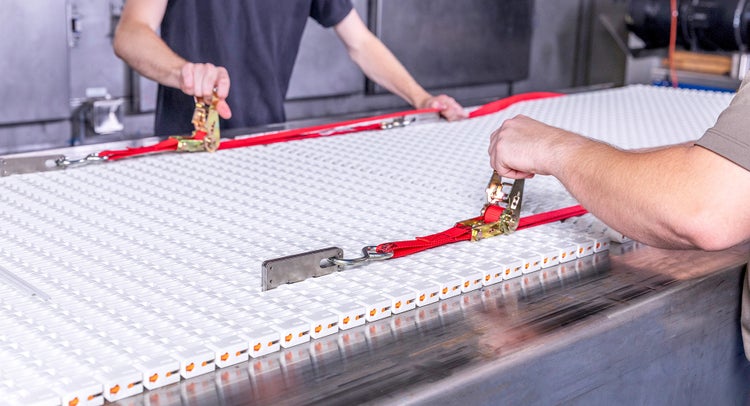

Add the Intralox Tensioner and change the paradigm: Using this custom tool requires only 1–2 operators for belt service and drastically speeds up the process. It eliminates opportunities for back strain and injury while pulling the belt. It also protects your belting from accidental damage. This one small investment will simplify your overall process.

Benefits

- Simplify maintenance

- Improve worker safety

- Minimize risk of belt breakage

- Require fewer operators for servicing

Download the PDF instructions for belt repair using the Intralox Tensioner for S1700 FG/FGNT belting

Specifications

- Belt widths up to 3 ft (1 m) require one set of tensioners

- Belt widths 3–6 ft (1–2 m) require two sets of tensioners

- Belt widths 6–9 ft (2–3 m) require three sets of tensioners

Why wait?

Order your Intralox Tensioner for S1700 Flush Grid/Flush Grid Nub Top belting today. Each set includes two stainless steel puller plates and one ratchet strap.

Watch this short video to see how easy tensioning your belts can be: