Increase Accumulation. Reduce Everything Else.

Lower your total system cost with Intralox S570 Tight Transfer belting and nosebar transfer unit for filled cans.

- Spotlight

- July 25, 2025

Lower your total system cost with S570 Tight Transfer belting and the Intralox nosebar transfer unit for filled cans. This end-to-end transfer solution for the beverage industry protects your time and budget while keeping your products safe from damage. It eliminates the frequent problems inherent with dead plates and side-by-side conveyor layouts.

A Better Tight-Transfer Solution for Filled Cans

Optimize Your Layout

Our solution reduces your layout footprint and requires less belting than competitive technologies. The efficient layout maintains throughput goals while allowing your belt to run at slower speeds. This advantage increases your belting’s lifespan.

Eliminate Transfer Risk

Your belt is only as good as its worst transfer. Our nosebar transfer unit is a cost-effective way to optimize production with no guesswork involved.

The unit is pre-engineered for optimal spacing, alignment, and waterfall. Its advanced design takes minutes to install and requires no adjustments—ever.

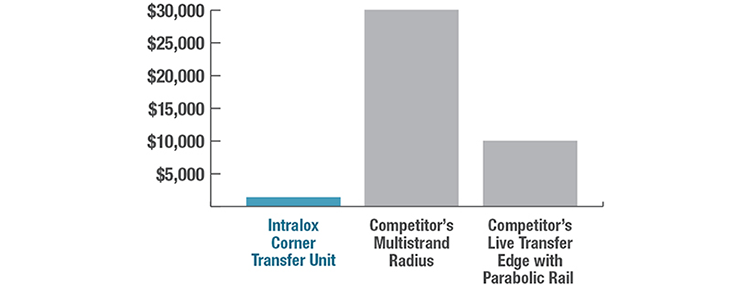

Spend Less on Corners

Intralox corners feature an elegant design with a lower acquisition cost. They also require fewer spare parts and less ongoing maintenance.

Lower Your Total Cost for Filled Cans

Savings Example (based on one customer’s installation):

- ~30% less belting

- Reduce acquisition costs

- Simple to install and maintain

- Eliminate can stranding, tipping, and damage

The Perfect Pair

Intralox S570 Tight Transfer belting and nosebar transfer unit are designed to work together perfectly. When used in combination, you can expect increased accumulation, fewer production risks, and longer belt life.

Eliminate Transfer Risk

To learn more about our Tight Transfer solution for filled cans, contact Intralox Customer Service.