JTM Reduces Cooling Time with Intralox Airflow Optimization

Case StudyJTM Food Group

Products

Spirals

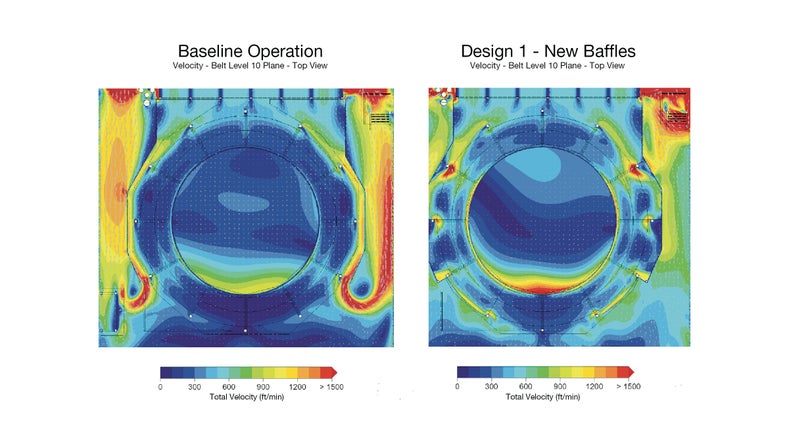

Evidence of overall airflow volume improvement, air waste reduction on left and right sides, and no-air-flow zone decrease when it is away from the fan (bottom of image)

Customer Challenge

JTM Food Group—a manufacturer of dips, soups, and other ready-to-eat foods—was looking to improve the performance of its spiral freezer to lower the temperature of pouched products in a shorter amount of time.

After products are cooked, they run through the freezer for 75 minutes and are stored in a case freezer for 24–48 hours before being released.

Current food safety regulations require product temperature to reach 40°F (4.4°C) within 10 hours after cooking. Facing a possible reduction of this timeframe due to regulatory changes, JTM wanted to ensure continuous compliance and reduce food safety risks.

Intralox Execution

JTM identified the freezer airflow as an area for improvement and partnered with Intralox to carry out the optimization.

Using proprietary airflow meters developed internally, Intralox built a real-time model of airflow throughout the spiral system. These data were used as input for computational fluid dynamics routines to explore how reconfiguring the system could lead to optimized airflow around the product.

The airflow modifications are having a positive impact on production performance, have greatly mitigated potential for any noncompliance chilling requirements, and improved food safety.

Jeff Wissel

JTM Food Group Plant Engineer

Intralox Optimization Services Group used the output of the computational fluid dynamics analysis to design new baffling that drastically improved air velocity over the product. The baffles were installed over one weekend with minimal impact to JTM’s production.

Results

With the new baffles, exit temperature from the spiral freezer changed by 20°F without an increase in energy used. Products in the case freezer can reach required temperatures faster, allowing JTM to comply with potentially stricter regulations, improve food safety, and potentially release products quicker from cold storage.