Belt Replacement Ruler

To learn more about this tool, watch our Belt Replacement Ruler Overview tutorial video or read the How-To Instructions below.

Intralox provides the Belt Replacement Ruler as a helpful tool, not as a substitution for a qualified Intralox representative.

Before using the Belt Replacement Ruler, please carefully review the information on this page, including the Disclaimers section below, and contact Intralox if you have any questions.

How-To Instructions

Step 1: Identify Your Belt

- Use our Identify a Belt tool to confirm that your belt was manufactured by Intralox and determine its series.

Step 2: Identify the Letter and Corresponding Scale

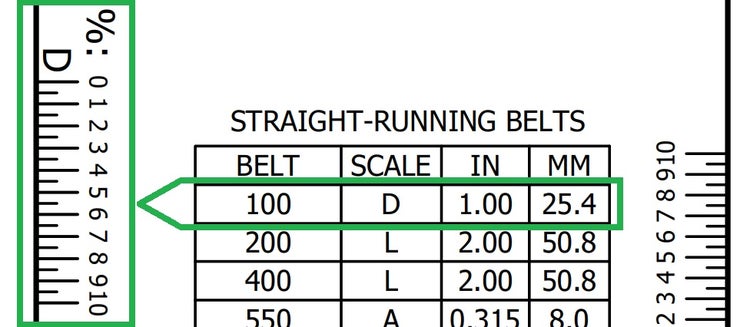

- Now that you know the Series number of your Intralox belt, find your Series number in the first Belt column on the ruler’s lookup tables.

- Once you have found the correct row, note the letter identifier in the second Scale column, then find the corresponding letter and scale on the ruler.

- Please note that the ruler has scales on the front and back of the ruler. If your letter has an asterisk next to it, your scale is on the side opposite the lookup tables.

Step 3: Measure Your Belt’s Elongation

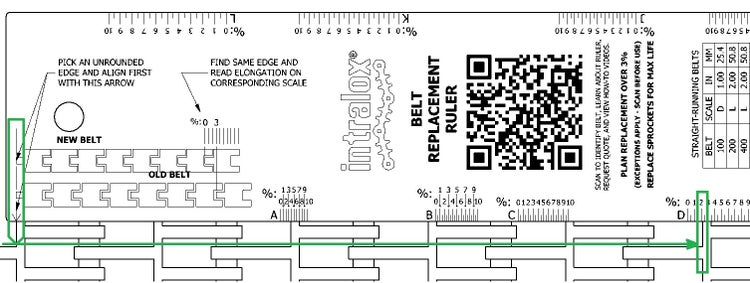

- Place the ruler on the belt with the large arrow to your left and your scale to the right.

- Pick an unrounded edge and align it first with the large arrow to the left. Avoid rounded edges since they will reduce the quality of the measurement.

- Next, locate the same unrounded edge further down the belt on a different section next to your scale. Use the corresponding scale to directly read the percent elongation; this will eliminate the need for module counting, a measuring tape, or calculations.

- If your belt has sections of varying age or wear—often due to repairs—measure multiple locations to ensure accuracy in your reading.

Step 4: Assess Risk and Plan for Replacement

- If your belt’s elongation is above 3%, Intralox recommends replacing the belt and sprockets. Old sprockets will not provide maximum belt life.

- Intralox belts are resilient, and a major failure at exactly 3% elongation is unlikely. To prevent unnecessary downtime, however, we recommend customers conduct their own risk assessment and plan replacements to mitigate risks associated with elongation above 3%. Decades of experience have shown that failures increase significantly at elongations above 3%.

- Use our Request a Quote form to request a quote on belts, sprockets, or associated components.

Additional Resources

- Our Performance Support Videos can help you address common conveyor belt challenges.

- For in-depth information about our belts, components, and accessories, download the Intralox Engineering Manual (PDF).

Disclaimers

Intralox recommends replacing your belts and sprockets at 3% elongation or greater. To better serve our customers, we also share information on safe belt elongation thresholds above 3% when supported by adequate data. See below for validated exceptions.

The Belt Replacement Ruler only measures belt elongation. Use this tool along with other indicators to determine belt health.

Exceptions

S4500 DARB Bulk Sorters and Flow Splitters

| Product | Threshold |

| DARB Sorter S4500 - Bulk Sorter | 5% |

| DARB Sorter S4500 - Bulk Flow Splitter | 5% |