The Gains of Going Low Tension or Tensionless

In belt drive systems, less—or zero—is more

- Insights

- May 10, 2021

The earliest product conveyors relied on friction as a primary function to drive belts. And while such fully tensioned systems are still in use today, conveyor technology has greatly evolved.

Over time, OEMs and food processors have increasingly opted for sprocket-driven low-tension or tensionless technology systems over those that are friction driven.

How exactly are these solutions different? In what ways has the technology evolved beyond tensioned systems?

Whether you’re planning to build new conveyors or thinking of retrofitting existing equipment, we’ve outlined the operational efficiency and food safety benefits that low-tension and tensionless belt systems can deliver in your facility.

Operational Efficiencies

In a tensioned system, the belt must be tightened to run correctly. When customers move away from this, numerous inherent benefits emerge immediately.

Improved Belt Life

When tension is reduced or removed from a belt system, less strain is imposed on the conveyor components. Since the belt isn’t working as hard, its life is extended. In sprocket-driven low-tension and tensionless systems, the catenary sag created in the returnway helps make this possible.

“This is very important because it has two functions,” says Cornel de Lange, Application Engineering Manager for Intralox EMEA. “Catenary sag helps to maintain low or zero tension in the belt, and it also allows for belt elongation or contraction.”

Catenary sag in low-tension and tensionless systems provides belt storage for thermal cycling.

Let’s say the temperature drops between sanitation and production. As the belt gets colder, it contracts and gets shorter on the conveyor. Since there’s loose belting in the catenary, the system can draw on that extra belt length to feed the whole circuit and remain low tension or tensionless.

This catenary sag in the returnway also gives the belt a chance to relax. When the belt is under load in the carryway, there’s tension. But as soon as it comes off the drive, that tension is removed.

“It’s kind of like taking the weekend off,” says Jim Honeycutt, Intralox ThermoDrive Product Manager. “The belt works Monday through Friday in the carryway and then in the returnway it relaxes, recharges, and gets ready for the carryway again.” In a tensioned system, the belt is effectively working seven days a week and never gets any downtime. No wonder its life is shorter.

Intralox Team Tip: When retrofitting, be sure to communicate changes with your plant’s maintenance team. They may view catenary sag as a problem and mistakenly add tension to your low-tension or tensionless belt system.

No Take-up Devices to Manage

Tensioned belts require regular adjustments. Operators use take-up devices to establish what they believe is the optimal amount of tension so that the belt doesn’t slip. But tension must be monitored and managed because it can change over time. Product load, ambient temperature, belt age, and how much the belt is stretched are all factors that can require tension adjustments.

Low-tension and tensionless systems don’t require take-up devices at all. In fact, our experts encourage customers doing retrofits to either disable their existing take-ups or remove them altogether. Why? The solution is already in place to drive the belt reliably and predictably.

Tensionless technology is a solution we created that allows us to drive a loose belt reliably and predictably on a conveyor.

Jim Honeycutt

Intralox ThermoDrive Product Manager

Reduced Mistracking

When belts are driven under tension, positioning can become problematic. “Your belt tends to move to the left or the right and you must constantly adjust it to keep tracking consistent,” says de Lange.

“Tension activates and amplifies mistracking,” says Honeycutt. “When you eliminate tension in the belt system, you deactivate and de-escalate mistracking. The lower the tension, the easier it is to manage mistracking. Once the tension is low enough, the belt system becomes self-managed. The behavior of the belt changes dramatically.”

In our low-tension and tensionless systems, the belt maintains engagement with the sprockets and stays on its intended circuit without external intervention. This reduces uneven belt wear, providing more uptime and reliability.

Intralox expert Jim Honeycutt demonstrates the benefits of a tensionless belt system.

Food Safety Benefits

Easier Access for Sanitation

In low-tension and tensionless systems, you have loose belt sitting in catenary pockets allowing the belt to be lifted on the carryway. This provides easy, immediate access for cleaning the conveyor daily with the least amount of effort. Belt circuit design is simplified with low-tension and tensionless belt systems, creating new opportunities in hygienic conveyor design, further improving sanitation access.

“That translates to brand protection, food safety performance, and food safety risk mitigation almost immediately,” says Honeycutt.

No Fabric Reinforcements

To prevent stretching, traditional flat belts often include fabric reinforcements within them. If the belt is damaged and the fabric exposed, it creates points for bacteria harborage.

A tensionless system allows OEMs and food processors to use belt materials that are unreinforced and extremely hygienic. “It lets you choose food-safe, solid, thermoplastic material that’s hygienic, robust, monolithic in design, and impenetrable from fluids or pathogens,” says Honeycutt.

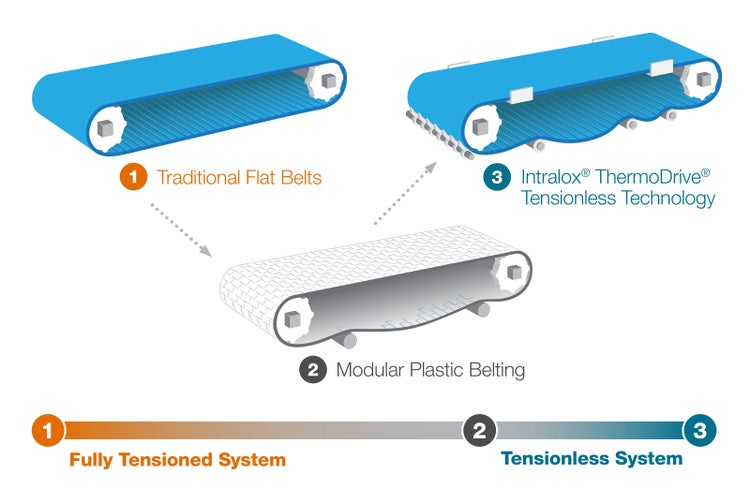

Until Intralox introduced modular plastic belting in 1971, all conveyor belts were tensioned and relied on friction.

Modular plastic belting was invented to address the inherent problems of metal belts. ThermoDrive belting was created to take food safety to a new level without sacrificing operational reliability.

So, why are tensioned belt systems still widely used today? Considering the enormous benefits of technologies that lower or remove belt tension completely, that’s a good question.

As Honeycutt puts it, “It’s pretty simple. When you take tension out, everything suddenly gets better. Quicker.”

Contact our technical support specialists to determine the optimal setup for your conveyor belt.