A New Mindset for a New Industry

Our Expert’s Roadmap to the EV Revolution

- Insights

- December 11, 2023

“The greatest challenge with producing EV batteries is that they can’t be thought of like combustion engines,” says Martina Costa, Business Development Analyst at Intralox. “Efficiently handling EV batteries requires new technologies and a whole new mindset.”

As the electric vehicle (EV) industry continues to grow its market share, a commonly invoked analogy is the invention of the automobile: Like automobiles replaces horses as the primary means of everyday transportation, EVs will soon overtake gas-powered vehicles.

What people forget is that automobiles weren’t mass-produced for another 30 years after their invention. German engineers built the first gasoline-fueled, four-stroke cycle engine in 1876. A decade later, Carl Benz began manufacturing the first commercial motor vehicles with internal combustion engines. It took another 12 for Henry Ford to start mass-producing his Ford Model T.

This decades-long experiment yielded a new world, and consumers today feel they’re on the cusp of a similar paradigm shift: EVs replacing gas-powered cars. But the EV industry hasn’t had a decades-long experiment yet. It hasn’t had 30+ years to refine its production processes.

No, the EV industry—still in its infancy—is being eagerly watched by consumers unaware of the extra challenges battery production presents compared to traditional automotive production.

Manufacturers are under pressure to handle extra weight, corrosive materials, and difficult dimensions. And they’re under pressure to do it now.

We caught up with EV expert Martina Costa to discuss the strategies and solutions she believes can help manufacturers succeed in this booming industry.

Strength and Speed

“This phase is all about EV batteries,” Costa says.

Costa boasts engineering experience in the tire, automotive, and EV industries, with specialties in product development and financial analysis. She’s helping create Intralox’s newest EV battery-handling solutions and has seen the rise of electric vehicles up close.

Her statement is definitive. She means that it’s time for manufacturers to equip themselves properly to move heavy, difficult EV battery products—and move them quickly.

“Increasing EV battery throughput is a big worry for car manufacturers,” she says. “They’re heavier than combustion engines, they’re delicate, and they come in more shapes and sizes. At the same time, manufacturers are under pressure to meet sales targets and beat worldwide competition.”

The automotive industry, however, is strictly regulated and takes a cautious approach to manufacturing vehicles and components. This will work against it moving into the EV era.

“Manufacturers like to be on the safe side, so they handle EV batteries like they’ve always handled combustion engines,” Costa says.

Ironically, this caution is a risky move both in terms of throughput and overall cost because combustion engine production lines are too rough for delicate EV batteries. Damage to EV batteries is expensive—more expensive than to combustion engines—and consistent damage will tank your throughput.

When it’s time for your operation to add or switch to EV production, your system needs to be designed with solutions that properly handle these new, difficult products.

Flexibility for the Future

“We used all our expertise to create something future proof,” Costa says. “Car manufacturers and EV battery producers need solutions that let them continue to adjust to new batteries, whatever the size, weight, and specifications.”

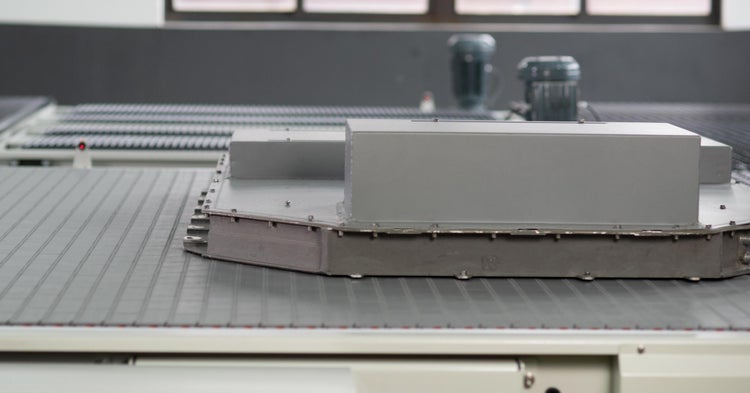

Solution flexibility is key not only because the industry’s products are evolving, but because successfully assembling even one of these products depends on several processes. Batteries start as cells, are turned into modules, and end up as packs—and each stage requires different settings.

“To optimize the cell and module stage—which requires precise, gentle handling—we built on our experience in the logistics industry,” Costa explains. “For battery packs, we used our experience in the automotive and tire industry, as that stage is more about moving heavy parts.”

As in those industries, automating these stages can be a good—and cost-effective—way to reduce human error and streamline each process. It also allows for data analysis, which can make it easier to respond when the market dictates changes to your process.

“Connecting data to every single process makes it easier to detect problems, adapt, and improve overall production flow,” says Costa.

Trusted Partners

In an industry trained to be careful with new technologies, getting companies to change EV battery production isn’t easy.

“That’s why we test,” Costa says. “I mean that in the broadest sense of the word. We give customers all the time and resources they need to figure out the best solution for them, both in our testing facilities and at their own production sites.”

When you choose Intralox solutions, you become our partner. We see your project through, start to finish: ordering, installation, and continued support.

Support is free of cost at Intralox. It’s what’s needed when you introduce a new technology to the market. You need to be there and be part of the change.

Martina Costa

Business Development Analyst at Intralox

We can collaborate with your OEM partners and your team to optimize your layout, meet specific production goals, or just successfully implement our technologies. And once you’re up and running, we’re not going anywhere.

“We aim to stay engaged with our customers rather than just sell our solutions,” she continues. “We bring innovation, but our customers bring experience with their specific production lines. Their engineers have been working on their systems for many years, so they know about their specific challenges.”

Intralox application engineers also visit our partners to provide health checks on existing equipment and trainings for any new developments and innovations—all free of charge.

“It’s needed when you introduce a new technology to the market,” says Costa. “You need to be there and be part of the change.”

What’s Next?

Will the industry standardize EV battery sizes? Will they become changeable instead of chargeable? Will they require adaptation for at-home storage?

“We’re working on all these questions already,” Costa says. “For instance, while EV mobility is now mainly in cars, we’ll soon have an increase in electric buses and trucks with heavy-duty batteries."

“It’s why we aim to create a lean, flexible production process.”

It’s also why we offer you the most comprehensive support in the industry.

Our Expertise. Your Future.

Ready for what's next? Our e-book offers an outline to help you develop strong, future-ready operations.