Managing Preventive Maintenance in 3 Critical Situations

- Insights

- August 17, 2020

In food processing plants, there are certain things you never want to hear, answer for, or experience: food safety complaints and unscheduled downtime.

Plant managers and maintenance personnel work tirelessly to avoid them. At the same time, you’re responsible for meeting higher throughput demands, handling labor shortages, and—of course—producing safe food.

None of those goals can be met unless the lines are operating safely and reliably. But even in the most well-designed, solidly constructed systems, equipment breaks and belts wear. What can you do to keep food safety issues and unscheduled downtime from happening in your plant? The answer is preventive maintenance.

Our application engineers and account managers have spent thousands of hours in facilities that process all types of food around the world. We’ve seen what can go wrong when preventive maintenance isn’t done well, and what can go right when it’s made a priority.

We’ve identified three critical situations that food processors face, and what you can do to apply preventive maintenance practices in each case to achieve operational excellence and food safety.

Increased Production

This is a tough—and increasingly common—scenario. But whether your lines run day and night, or at maximum rates to meet throughput goals, all is not lost. There is an easy and effective preventive maintenance measure you can take to keep the lines flowing smoothly and safely.

Prioritize Visual Inspections

“A lot of preventive maintenance can be performed with regular visual inspections outside of a maintenance period,” says Intralox Application Engineer Rejing Zhou. Here’s what you should look for:

Has the belt developed excessive catenary sag?

If your modular plastic belting (MPB) appears elongated, remove rows of modules as needed to shorten the belt.

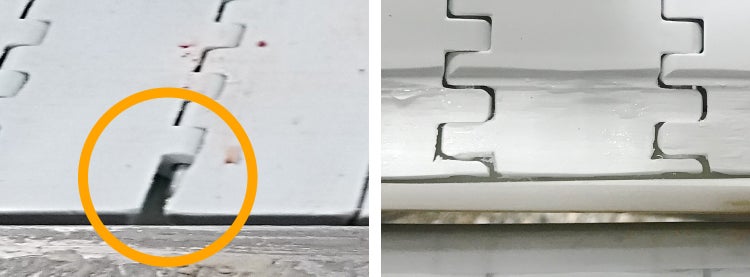

Left: An example of a damaged edge module. Right: An example of belt wear.

Are any of the plastic modules missing or damaged?

If so, use the correct tools to remove, repair, or replace the necessary parts.

How do the belt edges look?

If you spot damage or notice places the belt is wearing where it shouldn’t, inspect the conveyor for the cause and correct it.

Have you spotted belt-colored shavings or flakes on the plant floor?

This is a telltale sign that there’s damage somewhere along the belt. Inspect the belt circuit further to find the problem.

Does the belt appear to be snagging, rubbing against the frame, or jumping on the conveyor’s sprockets?

Consult with your belt supplier for help with troubleshooting the issue.

Additionally, if your plant uses Intralox ThermoDrive belts, make sure there’s no tension in the system. “ThermoDrive belting is designed to run tensionless to eliminate the downtime often seen with tensioning,” says Logan Clark, Intralox Application Engineer. “If the belt appears stretched, inspect it closely for damage and make the necessary system modifications and repair or replace the belt as needed.”

If done correctly, preventive maintenance can completely eliminate your unscheduled downtime.

Logan Clark, Intralox Application Engineer

Starting the System After Extended Downtime

Before we recommend how to prepare for a smooth startup, it’s important to see downtime situations as opportunities. Whether your plant is undergoing a seasonal or unscheduled shutdown, use this window of time to perform the system maintenance employees usually don’t have the chance to do.

Here are two approaches for taking advantage of an extended downtime situation:

- Mission critical – Identify the most important preventive maintenance tasks that can be performed relatively quickly.

- Milestone – Review the milestone checklists for your conveyors and belts and carry out the preventive maintenance tasks that are scheduled, due, or overdue.

If you don’t have a “mission critical” list of preventive maintenance tasks to be performed, start one by referencing your milestone checklists. What could you be doing regularly to ensure that systems and belts operate reliably?

Once you’ve made the most of your downtime from a preventive maintenance perspective, consider performing a full sanitation cycle on the conveyor. Over time, dust accumulates if you’re not running the belt. This can pose a hazard, particularly if you’ve had work done inside the plant during downtime. For example, abrasive dust that settles on soft, ThermoDrive belting can damage it if the system is restarted before a thorough cleaning.

Labor Shortages

If your facility is understaffed, keeping up with preventive maintenance may seem impossible. It’s not. You just have to think and plan a little differently.

Get Production Staff Involved

“Shift ownership to your production staff and educate them about what to keep an eye on,” says Zhou. “Those employees are there for eight hours at a time. Involve them. Train and encourage production to perform visual inspections on the belts during their shifts. If those employees observe and report potential issues, it will greatly reduce your risk of unscheduled downtime.”

Use Checklists

To maximize efficiency, always have a checklist for any preventive maintenance due to be performed on the belts. Strive to create lists for tasks that should be completed regularly; for instance, daily, weekly, monthly, quarterly, and yearly.

“The five-person crew with a checklist will be more effective than the 10-person crew without one,” explains Clark. When your plant is short-handed, arming your team with detailed checklists will make them more effective and efficient at carrying out scheduled preventive maintenance.

Intralox Team Tip: Make your production staff part of the preventive maintenance process. Train them to perform visual inspections and call attention to potential issues before they become major problems.

Neglecting preventive maintenance is, in the end, inviting trouble. It puts food safety, production, quality, and sanitation efforts at risk, and can even damage the company’s brand.

Remember that even during stressful situations, when you don’t think there’s time or staff available to perform preventive maintenance, you can do it! With creative and proactive thinking, there are ways to stretch your resources so you can get these critical tasks completed.

“If done correctly,” says Clark, “preventive maintenance can completely eliminate your unscheduled downtime.”

For more about the Intralox support options available to answer your preventive maintenance questions, visit our Customer Support page.