Choosing the Right Packaging Line Layout

- Insights

- May 18, 2020

Intralox experts in packaging line design can help you uncover hidden opportunities, safeguard your investment, and ensure you’re aiming for success not only once the project is complete, but for many years after.

When designing new packaging lines, the options companies have can be overwhelming. The quest to balance current resources with new technologies, all while achieving the best results, can quickly lead to confusion.

Wrong choices can be costly. As one corporate engineering manager for an international food company puts it, “We think about conveyance last and end up paying the price for it.” Even a cutting-edge line layout can become a burden if it’s not right for your plant or situation.

We think about conveyance last and end up paying the price for it.

Corporate Engineering Manager

Impacts of the wrong line layout can include:

- Decreased future flexibility

- Underutilizing assets or resources

- Overspending and increased total cost of ownership

With everything that’s at stake, how can you know which system to choose?

Evaluate Your Needs

Understanding the high-level differences between packaging line design types can help guide your decision-making.

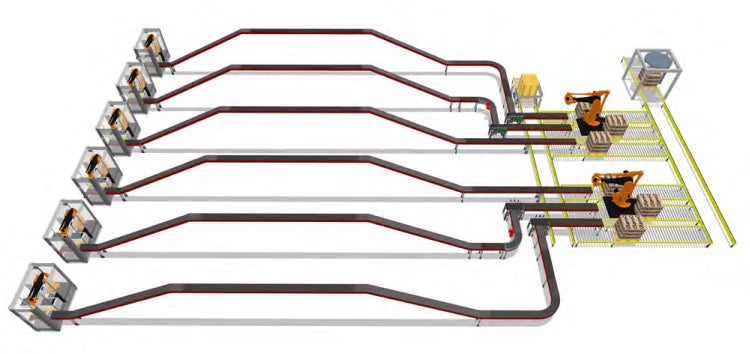

“The two types of palletizing philosophies are ‘end-of-line’ and ‘integrated,’” explains Brian Antkowiak, Intralox Layout Development Manager. “End-of-line palletizing simply uses direct conveyance from packaging lines to dedicated palletizers. Integrated palletizing includes some degree of merging, switching, or sorting, so that there is flexibility to route the output of the packaging lines to multiple different palletizers, with some palletizers potentially being shared among packaging lines. It is common to find a hybrid of both systems in plants that produce high volumes and many SKUs.”

With that in mind, an experienced decision-maker will succeed by adhering to the guiding principles of project execution:

- Understand the drivers behind the project or expansion

- Define the criteria for success

- Identify and rank the factors by which design choices will be evaluated

Integrated palletizing includes some degree of merging, switching, or sorting, so that there is flexibility to route the output of the packaging lines to multiple different palletizers, with some palletizers potentially being shared among packaging lines.

End-of-line palletizing simply uses direct conveyance from packaging lines to dedicated palletizers.

Consider Every Factor

That third principle—“Identify and rank the factors by which design choices will be evaluated”—is especially crucial. Some criteria – like upfront system costs, project timelines, or throughput goals – will be clear to all stakeholders throughout the process. Others, however, can slip through the cracks.

Christoph Lemm, Intralox Global Engineering Manager, says, “A common topic that is overlooked in the system design and evaluation process is the palletizer unplanned downtime risk mitigation plan. How do you adjust production scheduling to meet sales orders? Can production be offloaded to other lines? Is manual palletizing or co-packing an option, and if so, what are the safety and cost implications?”

In addition to upfront costs and production capacity, it’s important to thoroughly consider:

- Total cost of ownership, including operational, maintenance, and energy costs

- Future readiness

- Safety, downtime, or production scheduling risks

- Controls complexity

- Available floor space

A Guiding Hand

Even when every factor has been considered and prioritized, you may still question whether you’re headed in the right direction. An outside perspective can be helpful, especially if your company or plant hasn’t undertaken such a project in recent years.

As Intralox Global Industry Team Leader Joe Brisson notes, “There are so many options from a conceptual design standpoint, let alone technologies applicable for each design, all with varying benefits depending on project priorities. It’s almost unreasonable to expect a company that doesn’t work in this area every day to understand all that’s out there without additional guidance.”

Consulting with experts early in packaging line design can help you uncover hidden opportunities, safeguard your investment, and ensure that you’re achieving your key objectives, not only once the project is complete, but for many years after.

Intralox’s Packer to Palletizer experts can partner with you on back end projects to ensure maximum return on investment. Visit our Packer to Palletizer page to learn more.