Calculating True Total Cost of Ownership

5 keys to making the best equipment decisions for your plant

- Insights

The Total Cost of Ownership for a capital project is much larger than what you can see on the price tag of a piece of equipment.

Imagine that now is a great time to buy a new car. (It isn’t, but take the ride for a moment.) Early in the decision-making process, you weigh whether to go with a gas-powered or an electric vehicle (EV).

Initially, the purchase price of a gas vehicle may seem to make it the more affordable choice. But when you compare the operating expenses—fuel costs and oil changes, for example—an EV that’s more expensive to buy up front is much cheaper to drive per mile over the long term.

Similarly, when choosing equipment for your food processing plant, it’s best to calculate the Total Cost of Ownership (TCO) and not decide solely on the upfront cost. But what factors should you consider beyond the initial investment?

Our experts share the keys for optimizing the TCO of proposed equipment to ensure it positively impacts your plant’s operational efficiency, food safety, and bottom line.

Initial Investment

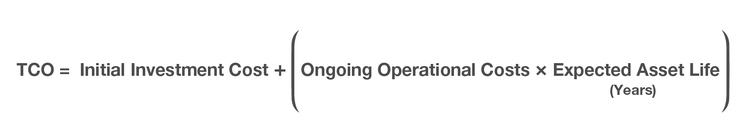

Calculating the TCO of a piece of equipment involves a simple equation:

The catch? There are numerous variables at play. Even the initial investment cost involves much more than the price tag on the equipment itself.

“You need to ask yourself, ‘How many laborers will it take to retrofit or install the equipment? How long will the process take? What is the cost per hour of downtime?’ All those things are part of your initial investment,” says Helen Xi, Intralox Business Development Analyst for the Bakery and Snack industry.

But as both the TCO equation and our vehicle analogy indicate, you must consider all potential operational costs—and savings—of the equipment as well. What is the estimated long-term cost of ownership?

Training

When calculating TCO, think about the potential need for training. Will there be costs associated with getting your staff up to speed on the proposed equipment? This is often an underestimated or overlooked expense.

“Obviously, the more complex the piece of equipment is to operate or clean, the more training is required,” explains Brad Klemme, Commercial Food Sanitation Senior Food Safety Specialist.

The best capital investments not only run reliably, but are also hygienically designed, simple to use, and easy to clean–and therefore require little training. This is critical because of another concern: Labor.

Labor

We all know that labor is more expensive and harder to find than it was just a few years ago. To combat this challenge, many food manufacturers have turned to automation.

Capital projects that automate your line must also be evaluated for cleanability. Is your proposed automation equipment designed to be wet cleaned? Technology such as Active Integrated Motion™ (AIM™) can reduce not only production labor, but sanitation labor as well.

“Automation doesn’t always bring simplicity or ease of cleaning to your operation,” says Klemme. Consider how complex the proposed equipment is. Will it require staff with more technical knowledge and training?

A piece of equipment that’s more hygienically designed, and can be cleaned more efficiently in less time, could potentially decrease the total amount of sanitation crewing you need during each cleaning cycle. “With the revolving door we see in staffing at food plants,” he says, “it’s best to choose equipment that’s easy for laborers to operate, clean, and maintain.”

Total cost of ownership is more than a number on a spreadsheet. It’s a conversation with our customers to understand their projects so we can deliver the right solution.

Helen Xi

Intralox Business Development Analyst for the Bakery and Snack industries

Maintenance

How much time and effort will it take to keep your capital investment running smoothly? Maintenance labor is one of the most expensive sectors within a plant from a cost standpoint.

Think also about your existing equipment. For example, a plant with a subpar spiral conveyor may have grown used to—or even complacent about—the amount of maintenance it requires. But spending six figures each year on maintenance to keep it running doesn’t need to be part of owning a spiral system.

“What costs are you regularly incurring? Are any of them tied to issues that increase your company’s food safety risk?” asks Elizabeth Cobb, Intralox Business Development Analyst for the Meat, Poultry, and Seafood Industry. “Don’t get comfortable with frequent equipment issues. You might forget there’s actually a problem. You wouldn’t drive on your spare tire forever, right?”

Team Tip: Considering a major capital investment? Ask your OEM for a reference installation case. Visit a plant where you can see your proposed equipment running and ask questions about how well it operates.

Flexibility

COVID-19 taught the food industry a lot. One of the biggest lessons was the importance of line and product flexibility. When restaurants closed due to lockdowns, consumers cooked more at home. Processors had to pivot from packaging 400 burgers together for a Quick-service Restaurant (QSR) to boxing 15 patties to sell through a retail grocer.

“We showed one of our customers a hypothetical scenario,” says Cobb. “It would replace an existing line equipped to supply QSRs with a dual-purpose solution that could easily transition to package for retail as well.” Reconfiguring line layouts with future-ready equipment can reduce maintenance, increase floor space, and minimize downtime.

Over the multi-year life of that type of solution, your return on investment will be much greater. Look for this kind of flexibility in new or retrofit projects to help calm any initial sticker shock.

Make your case for the capital projects you know can improve your plant’s throughput, food safety, and financial goals.

The TCO Calculation and Comparison Sheet (PDF) is a great place to start. Consider all the possible costs associated with upgrading your facility’s equipment and you’ll be better prepared to justify the expenses to plant management or ownership. Lean on the expertise of your OEM and belt supplier early in the process. They have the knowledge to help you make the right choice and set your plant on the road to success.

Have questions about calculating the TCO of new equipment? Connect with our food industry and technical experts to get the answers.