The Edge of Possibility

Side Drive technology's unique capabilities create infinite opportunities for conveyor length and design

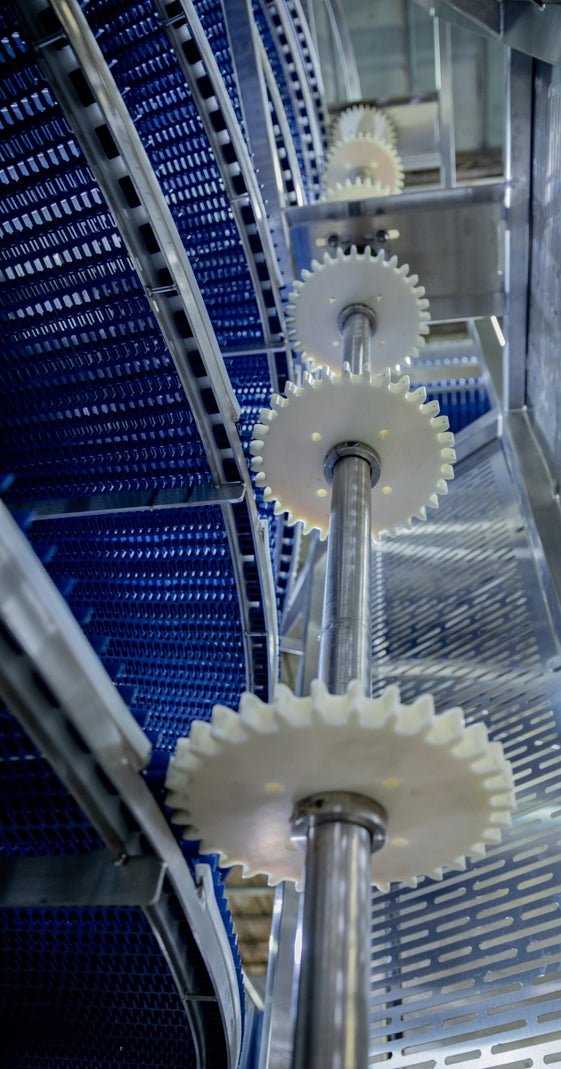

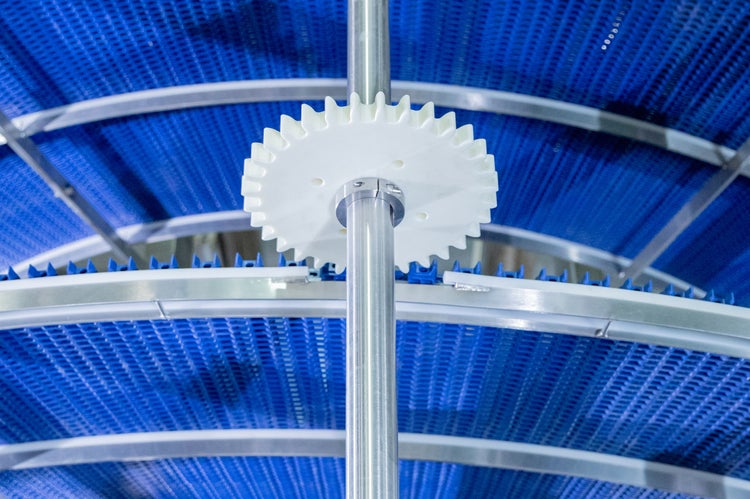

Side drive conveyorsSide Drive allows for infinitely long conveyors capable of turning both clockwise and counterclockwise.

The flexibility and easy maintenance of Intralox Side Drive technology enable unique configurations and eliminate transfers between equipment, all while being fully washdown ready.

Sprockets drive the belt from the edge at one or more points, using one or more drive motors. Side Drive is built upon Intralox’s advances in modular plastic conveyor belting and spiral conveyance, which ensures simplified maintenance and sanitation and better belt performance. By minimizing transfers, Side Drive also substantially reduces product damage and loss.

The Intralox Side Drive cooling towers run 24/5 in our Provo facility without issue. They’re reliable, easy to use, and have made our manufacturing floor both quieter and safer.

Scott Leek

Rimports Chief Engineer

Benefits

Side Drive technology offers many benefits, including:

- Enables flexible conveyor design options

- Accommodates infinitely long belting

- Fully washdown ready

- Minimizes transfer points to improve product quality and yield

- Increases efficiency and belt life

Applications

Where can Side Drive make the difference for you?